The term “refrigerator invented by Einstein and Szilard” is often used to refer to one of three refrigerator designs developed and patented by the two scientists in Germany in the 1920s. Accidents with electric refrigerators, including their hazardous refrigerants, were not unheard of at the time. Avoiding leaks of refrigerant was a top priority for Albert Einstein and Leo Szilard; therefore, they set out to design refrigerators without any moving components. In the early 1920s, they filed patent applications for three distinct refrigerator forms, each of which postulated a different physical and chemical process.

At Einstein’s residence in the mid-1920s, Szilard would often join in on conversations with Einstein’s colleagues and students from the Kaiser Wilhelm Institute for Physics in Dahlem, a Berlin suburb. They had some rather heated discussions every time they came upon a news story about a family that had died because of a refrigerant leak.

One of Einstein’s refrigerators used no electricity or Freon to operate.

The Main Ideas for a New Refrigerator

Leaks of the chloromethane, ammonia, or sulfur dioxide that were often employed as refrigerants at the time would have been disastrous. With no moving parts, potentially dangerous items like gaskets and seals would be unnecessary in their ideal refrigerator design.

They came up with many innovations, including three separate refrigerator designs that use various physical mechanics. Szilard made the primary contributions to the bulk of the innovations that resulted from these patents, while Einstein helped with consultations and the production of patent documents for a number of nations.

- The gas-absorption refrigerators that are already in use were the inspiration for one of their ideas.

- The second method entailed the release of pressurized water, which caused the tank’s remaining methanol to evaporate.

- In the final plan, an innovative method, electromagnetic induction, was used to move liquid metal through a conduit.

Attempts were made to create working models of these fridges. Engineer and Szilard acquaintance Albert Kornfeld helped Einstein and Szilard reach out to firms that were interested in taking on the project. Kornfeld built a prototype gas refrigerator and showed it off at Charlottenburg Technical University.

1: Gas Refrigerator

The Swedish business Electrolux, which made gas refrigerators at the time, paid 3,150 marks for the patent in 1927 via a subsidiary. Electrolux did not use the patent in the development of their refrigerator.

2: Water-Ejected Refrigeration

Citogel, a Hamburg firm (which means “quick freeze”), initiated a partnership for the model working with water ejection. The concept was simple: it needed just the pressure from a water pipe and some methanol to operate, making it ideal for localized cooling without the need for electricity.

In 1928, a working model was shown in Citogel. However, it was found that methanol was more costly than expected and that it was impossible to get the necessary water pressure from the water pipes owing to changes in water pressure across various locations and levels of the structure. Thus, attempts at commercialization were abandoned.

3: Liquid Metal Pump Refrigerator

The liquid metal pump refrigerator that Einstein and Szilard developed showed the greatest promise as a design. It was expected that this fridge would function in the same way as a regular fridge by compressing the flowing liquid metal serving as the refrigerant.

In the original concept, a magnetic field was applied perpendicular to the liquid metal’s surface and an electric current was sent straight through the metal to generate flow through perpendicular Lorentz forces.

Due to its poor electrical conductivity, however, mercury was a poor choice as the liquid metal. The sodium-potassium alloy that replaced it was extremely reactive and might have caught fire or exploded if exposed to air or water. In addition, it deteriorated the insulation of the electrodes used to produce current. It was necessary to hermetically seal the system; thus, the original concept was tweaked to use induction to power the system from outside coils. It was decided that it was still worth pursuing, despite being far less efficient than regular pumps.

In 1928, AEG started testing refrigerator prototypes using this pump. Kornfeld worked for AEG, and Szilard consulted for them. At AEG, Einstein checked the refrigerator prototypes at many stages of manufacturing, and Kornfeld reported to him at his house on more than ten occasions.

The Great Depression hit Germany in 1930, and the Nazis gained power, casting a pall over the country’s economy and politics. Around this time, Szilard questioned Einstein about whether or not their refrigerator could be manufactured in Europe.

Cancellation of the Einstein-Szilard Refrigerator Project

Due to the creation of tiny bubbles, the AEG prototype was so noisy that the Hungarian scientist Dennis Gabor referred to it as “howling like a jackal.” The prototype began running continuously in 1931, when the noise was adjusted to a tolerable level. The investigation into heating the liquid sodium rather than the liquid metal proceeded in an effort to increase energy efficiency.

However, research conducted in the United States the year before showed that Freon, which is completely safe for human contact, could be utilized as a refrigerant. AEG’s declining performance and a cooling market led to the Einstein-Szilard Refrigerator Project‘s cancellation in 1932.

In 1933, when the Nazis took control of Germany, both Einstein and Szilard were forced to leave the country. The United Kingdom and the United States both rejected Szilard’s attempts to introduce his liquid metal pump refrigerator. However, the Einstein-Szilard liquid metal pump itself, based on an invention by Szilard, was used to circulate coolant in early breeder reactor experiments in the 1950s.

Einstein-Szilard’s Gas Absorption Refrigerator

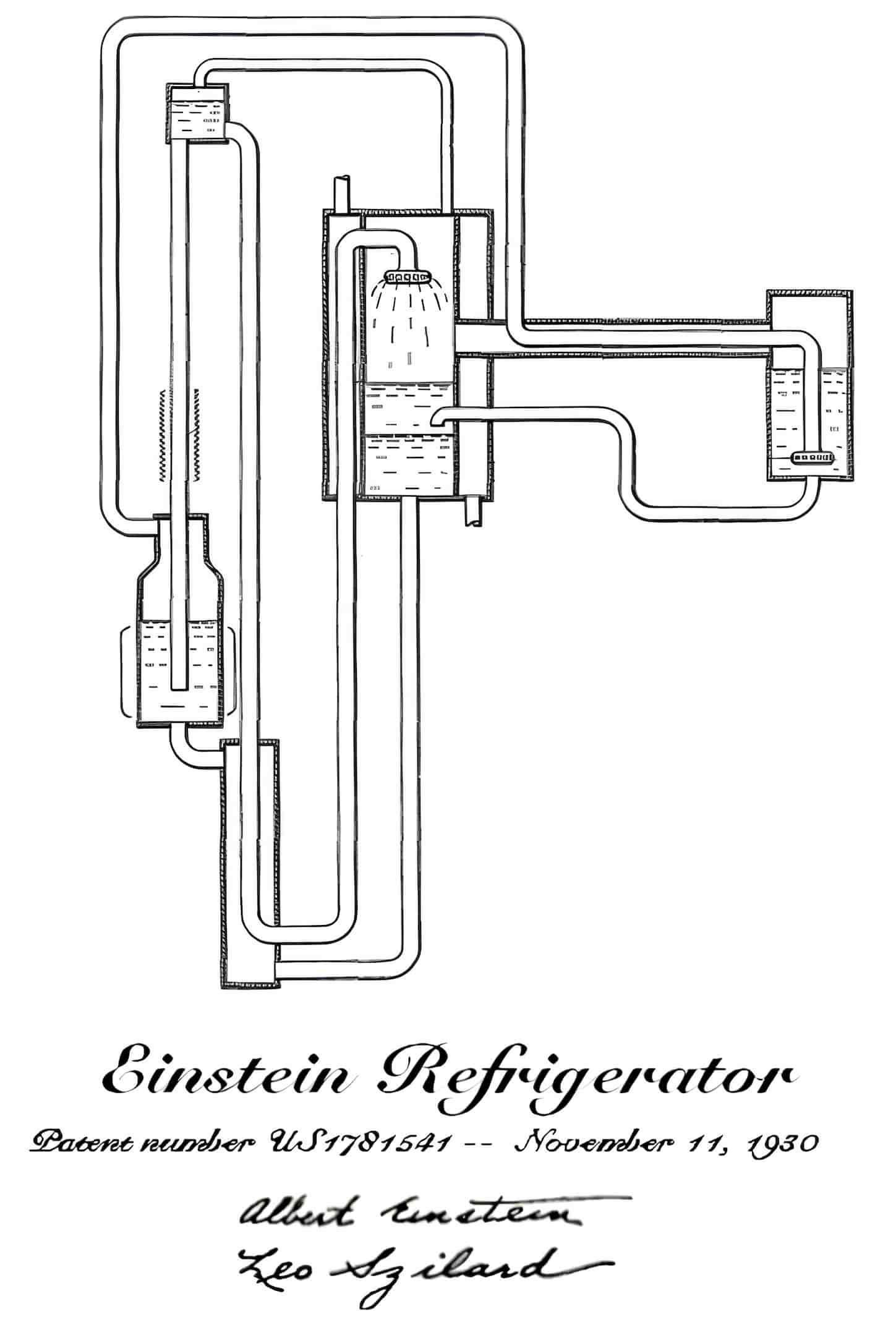

A gas-absorption refrigerator was also one of Einstein and Szilard’s creations; it had no moving components, maintained a constant pressure, and ran on nothing but heat. U.S. Patent 1,781,541 was issued to Einstein and Szilard on November 11, 1930, for their 1926 invention.

The original innovation on this concept was put forward in 1922 by Swedish innovators Baltzar von Platen and Carl Munters, and Einstein-Szilard’s design was an alternate version of their work.

How Did It Operate?

This Einstein-Szilard refrigerator functioned in the same way as a gas absorption refrigerator, namely as a single-pressure absorption refrigerator. Water served as the absorbent fluid in the refrigeration cycle, which also employed ammonia as the isobaric fluid and butane as the refrigerant. There were no moving components, and it could run on just about every kind of heat source you can think of, from a tiny gas burner or electric heater to the sun.

If you filled Einstein’s refrigerator with regular fluids, the water pump would double as an ammonia pump, and the ammonia pump would double as a butane pump. Ammonia could be extracted from water with relative ease because of its high solubility in cold water and its quickly decreasing solubility in hot water. Because of its low boiling point and insolubility in water, butane was selected for use as a refrigerant in this model by Einstein and Szilard.

In a mathematical sense, the evaporation temperature of the refrigerant on the low-temperature side of traditional refrigerators is a function of the pressure. Evaporation involves the absorption of heat and the transport of vapor to a compressor. At a certain temperature, the refrigerant vaporizes and combines with the vaporous ammonia to form a total pressure that is close to the system pressure. Without needing to be pumped, the mixture is sent straight to the ammonia absorber.

Compression raises the pressure of the refrigerant vapor, permitting condensation at relatively high temperatures on the high-temperature side of traditional refrigerators. In Einstein’s refrigerator, the ammonia absorbent raised the partial pressure of the refrigerant vapor to do the same thing.

The refrigeration process in absorption refrigerators involves the dissolution of ammonia vapor into water. The almost constant pressure of the mixture during flow aids in this process. As a result, the refrigerant partial pressure gets close to the system partial pressure, facilitating effective condensation and heat transfer to an exterior radiator, as is the case in conventional refrigerators.

Because it is insoluble in water (particularly butane), the condensed refrigerant floats and separates readily, allowing it to be recycled back into the evaporator. Meanwhile, ammonia vapor is separated from the heated ammonia-water solution and transported to the evaporator.

You read the primary idea behind Einstein’s refrigerator. In actual applications, this interaction between liquids and gases requires additional components. The refrigerator Einstein designed actually ran quietly, cost nothing to make, and lasted a long time.

Refrigerators Now

Because of the potential for carbon monoxide poisoning, gas refrigerators are being phased out. Despite recalls beginning in 1990, the U.S. Consumer Product Safety Commission (CPSC) issued a warning in 1998 that there had been 20 carbon monoxide-related fatalities in the United States and 60 in Canada attributed to these refrigerators. Prior to 1957, gas refrigerators seldom had enough ventilation.

In 2008, University of Oxford researcher Malcolm McCulloch presented a three-year strategy to improve the durability of absorption refrigerators for use in remote places without access to electricity. His group has developed a prototype with the goal of quadrupling efficiency by changing the layout and the fuel source.