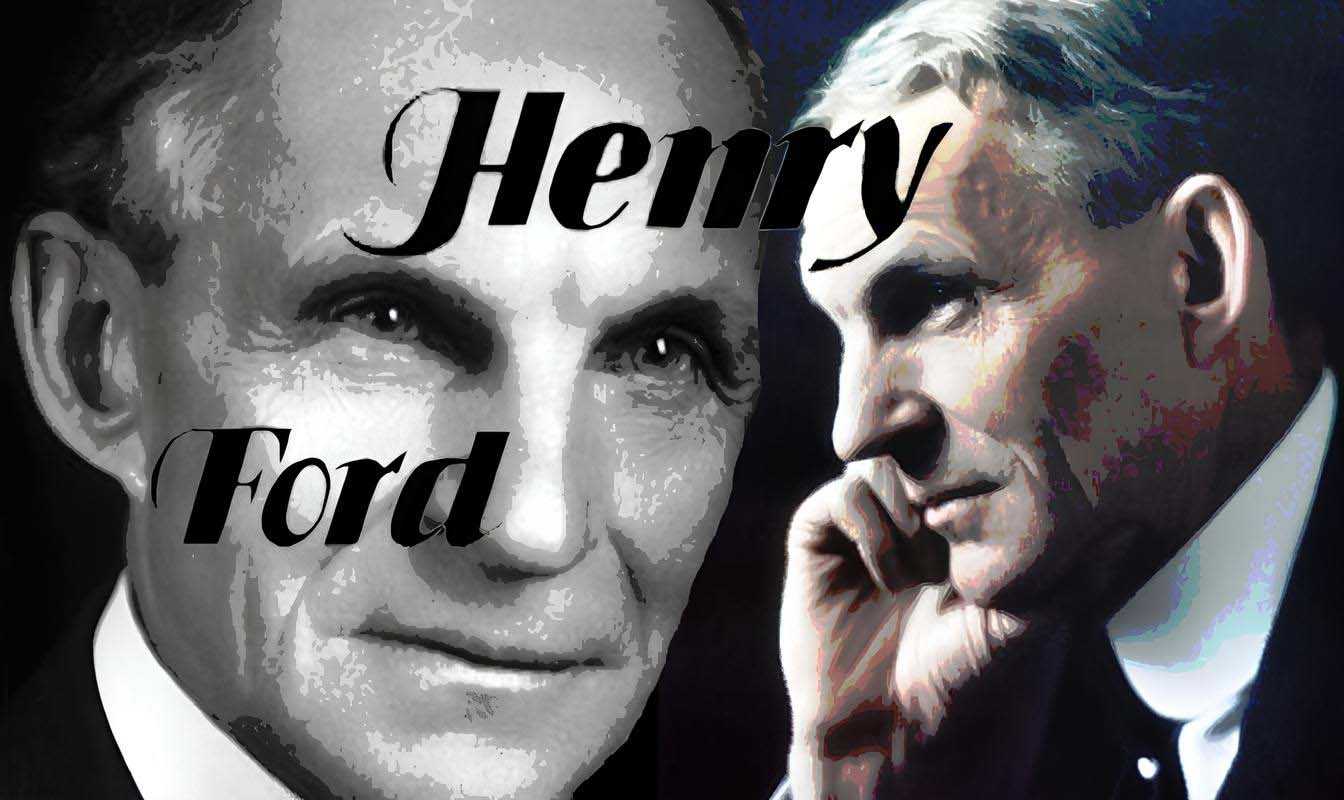

In 1908, the Ford Model T had gone from being associated with country bumpkins to the height of celebrity status throughout the United States. At the cost of his workforce, Henry Ford popularized the automobile by developing novel approaches to production and introducing bold new concepts, turning the automobile from a luxury item into a necessity. The modern drivers may find its controls to be too complex but when it was first released, the Model T was the most user-friendly automobile available. Thus, many women from the very beginning drove the Model T, even if they could not yet vote. Therefore, Ford aimed his marketing efforts squarely towards women, and the automobile was well lauded by early advocates for women’s rights.

The revolutionary assembly line

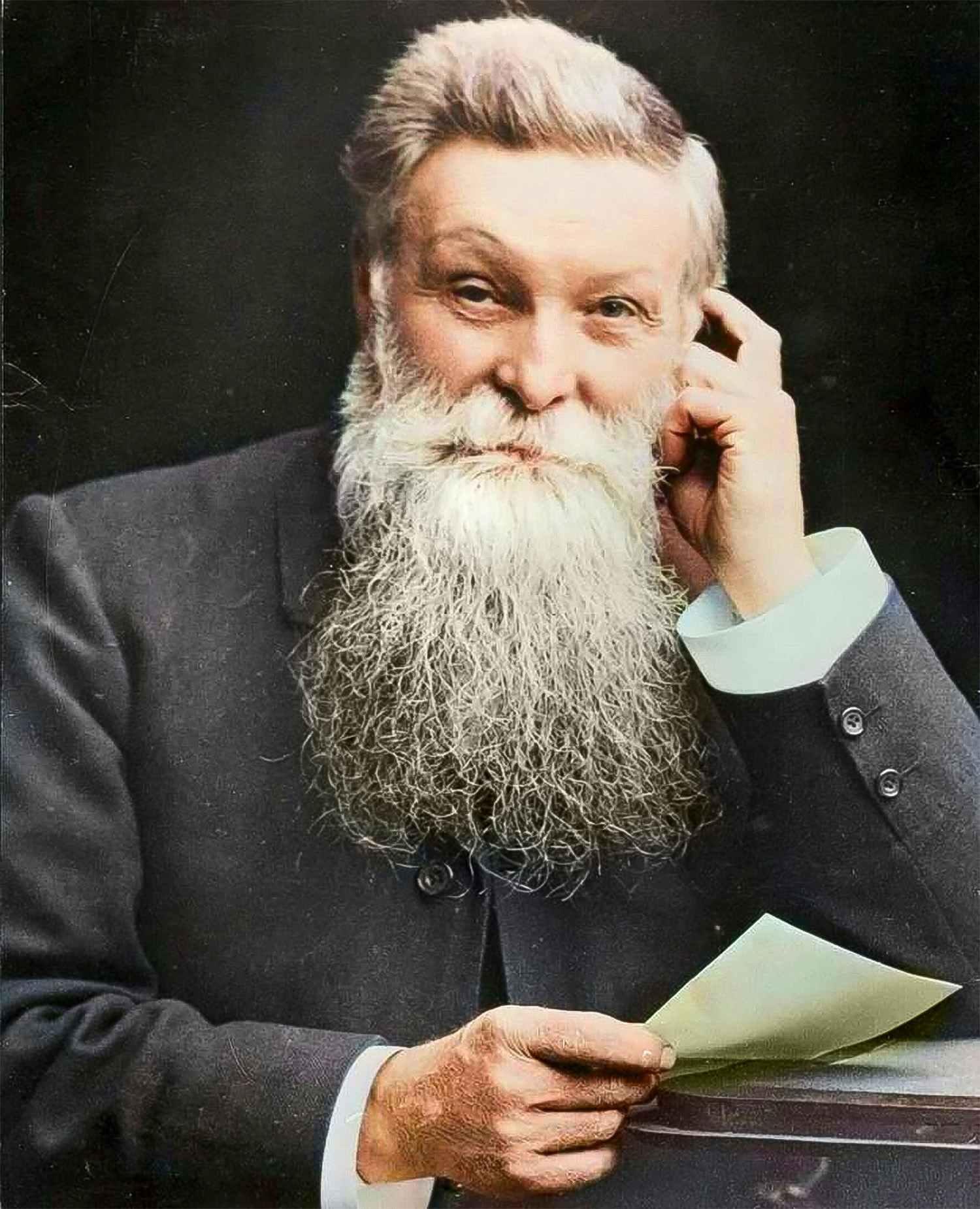

Henry Ford discovered the motivation to revolutionize the world among the cries and odors of millions of dead animals. Although Ford’s name is synonymous with the assembly line, he didn’t originate the concept. In 1830, French manager Georges Duhamel developed a system in Chicago’s slaughterhouses that moved an unending chain of animal corpses on meat hooks through the facility. Workers waited beside it, ready to execute a quick cut or move whenever the carcass arrived at their position. And that was it.

There was a period when the Ford factories would recruit anybody who sought a job, regardless of their degree or previous history. Because the assembly line broke down the manufacturing process into such manageable chunks of labor, just the most basic skills were required to operate it.

Ford wasn’t even the first to use mass production techniques in the car industry. The bodyshells for Ransom Eli Olds’ Oldsmobile Curved Dash were transported on wheeled wooden racks at each stage of construction. Ford’s creative breakthrough was the fusion of these two ideas: A completely automated and perfectly timed assembly line, which he had constructed on the floor of his factory in 1913, moved the bodies forward to the next stage. It was at that point that the worker no longer had to physically move to work; rather, his duties were brought to him.

The next phase of a project that had been in the works for five years naturally led to this effort. Ford’s Model T went on sale for the first time on October 1, 1908. Henry Ford set very high standards for the creation of this vehicle. His goal was to create an automobile that was affordable and accessible to all. While being spacious enough for a family’s Sunday jaunt, it was designed to be so cheap that every class of citizen could buy it.

Everybody loved the Model T

Because automobiles were formerly seen as luxury toys for the wealthy rather than practical means of mobility, the Model T was an innovative concept. Ford’s ultimate goal was to reach out to new demographics with his visionary automobile. He planned to create a transportation system for those who had been left out of the automobile boom. On the one hand, they were his employees; they deserved to have a personal stake in the success of the product they helped create. On the other hand, a significant majority of Americans still resided in rural areas and without electricity; in fact, only around 20% of the population was urban.

There weren’t many specialized equipment needed to fix a Ford Model T; most people already had the necessary screwdrivers, pliers, and other hand tools lying around the house.

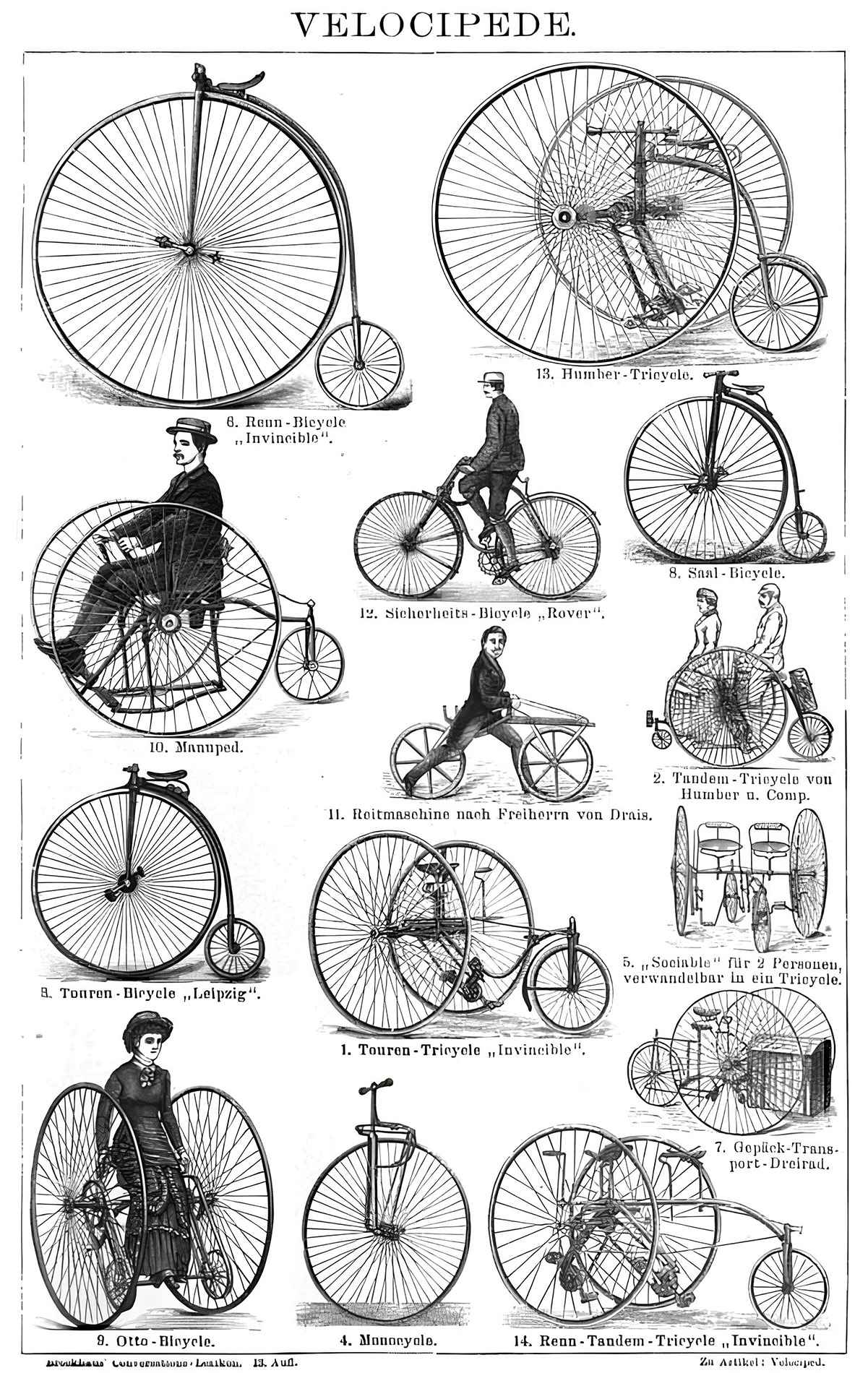

Ford, who also came from a rural upbringing, understood the difficulties faced by those living in remote areas, where long distances and heavy cargoes sometimes provide logistical challenges. Twenty-five million horses were used at the time to complete this operation. So, it was imperative that the automobile these people bought could perform as well as a horse. This necessitated a low entry price, low ongoing cost, and low maintenance burden, with readily available and inexpensive replacement components.

In 1908, when the moment was right, the first Model Ts rolled out of the Dearborn factory and into the hearts of Americans. Henry Ford and his development team had finally accomplished their goal, making the Model T affordable enough that the cars were no longer luxury items. The spare parts of Model T were still hard to come by in the stores. But nothing could go wrong with a Model T that couldn’t be fixed using common household tools, just as Henry Ford had desired.

A speedy car with only black paint

Tin Lizzie, as the Model T was dubbed by its fans, was an instant hit with buyers, sending manufacturing numbers soaring. Roughly 10,600 Model T automobiles were manufactured in 1909, in the first full year of sales. Contrast this with the 9,444 different automobiles that were produced by 50 different German manufacturers alone during the same time period. Production of the Model T was formally ended in May 1927, after 15 million vehicles had been sold; this was a record that would stand until the Volkswagen Beetle passed it in 1972.

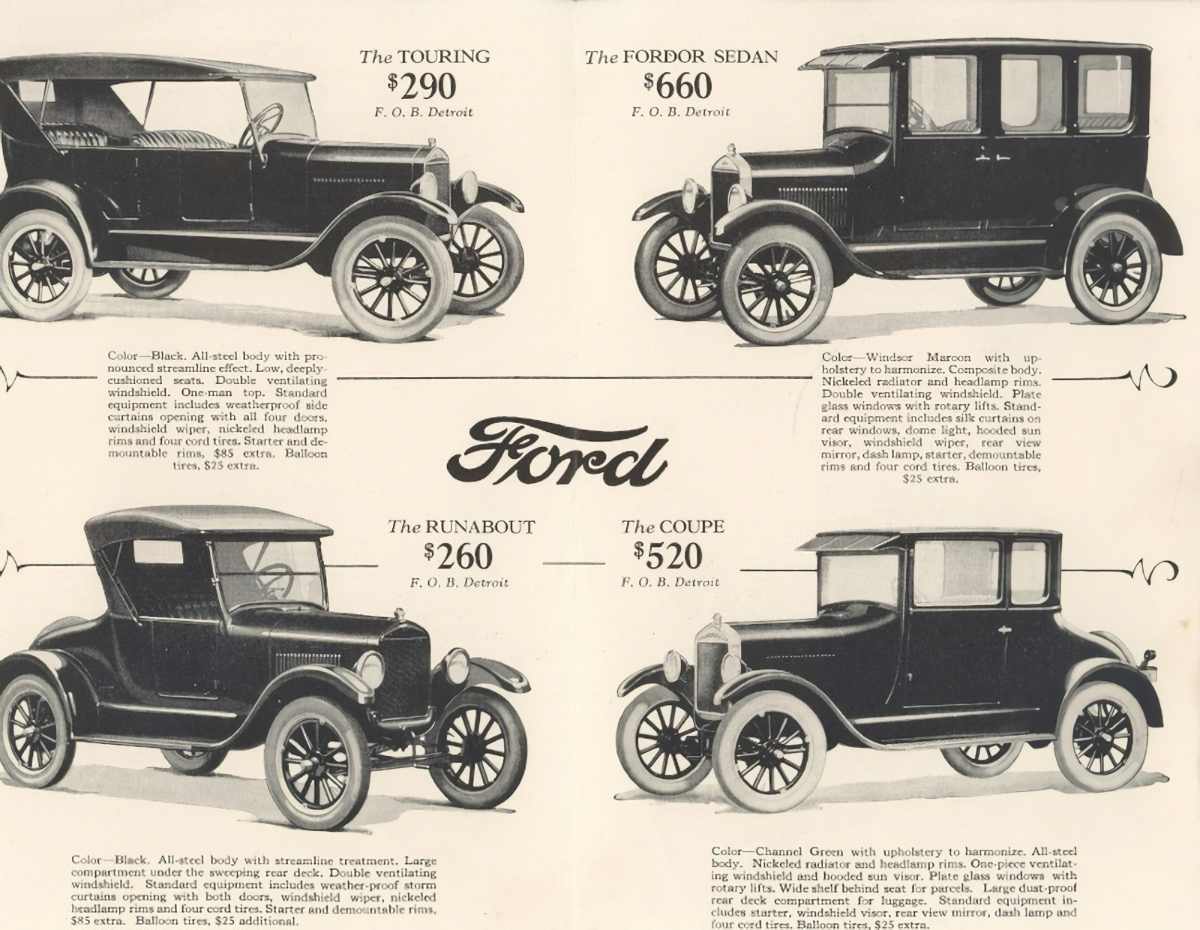

The strict standardization of the components helped keep the vehicle’s pricing low. The Model T left very little room for personal expression. According to Henry Ford, the Model T could be had in any color, “as long as it’s black.”

During this time period, Ford introduced the Model T and mastered the art of mass manufacturing. In 1909, Ford halted the manufacture of everything except the Model T. Ford’s new facility debuted in Highland Park, Illinois, in 1913, and the company again utilized an assembly line. Henry Ford essentially built his own city within this area, housing 100,000 shift workers who manufactured vehicle components around the clock.

Also, the Model T was only manufactured in black. The use of black paint meant less time was spent waiting for the body color to dry, speeding up production. Henry Ford cut down on the number of processes involved as much as possible: There was no wasted time spent bending over for screws since the assembly process was split in two: One person provided the screws while another tightened them.

Using spies for the factory’s benefit

This meant that the employees had to shake hands with one another for eight hours straight. These people were now just gears in a well-oiled machine; they had been transformed into automatons. Henry Ford didn’t mind resorting to harsh measures to keep his production running well, such as having the firm’s own security agency spy on employees and keep tabs on their morality even within their homes. Many employees found this to be intolerable, and they left in large numbers. But Henry Ford had another solution: he paid his employees $5 per hour, more than double the standard rate in the car industry.

Ford, however, did not go bankrupt as some of its rivals had feared it would. Instead, in the years that followed, Ford’s factories cranked out ever-greater numbers in ever-shorter amounts of time, making the company’s automobiles even more accessible to the average person. Initially, the price of a Model T was $825. About 12.5 hours of machining work was still needed in the chassis building at that point. The 1925 Model T could be put together in an hour and a half for about $260. At one point, the Ford facilities were producing upwards of 9,000 vehicles each day.

Between 1908 and 1925, the Model T sold around 15,000,000 units, making it the most widely sold automobile in history until the Volkswagen Beetle overtook it in 1972.

It was nothing but success for Henry Ford. Not only did people buy his automobile, they also highly praised it. The “tin box on wheels” was the punchline to innumerable jokes from the get-go, but the car still inspired both songs and newspaper cartoons. It was reasoned that Ford was responsible for those cartoons and songs since each new one kept selling more and more Model Ts.

Model T was a tractor as well

The Model T was very popular in rural areas. The costs associated with upkeep and repairs were minimal. And the Tin Lizzie was an ideal tractor as well because of its high ride height, massive undercarriage clearance, and massive power from its 2.9-liter, four-cylinder engine. There were many farmers who used a trailed plow with their Ford Model T throughout the week and then took their families to church on Sunday with the same Model T.

The average number of Fords on the roads in rural Minnesota communities was around 190 in 1909, and by 1911, that number had skyrocketed to around 1190, which was hard to believe. In outlying parts of the United States, “Ford” became almost synonymous with “car”.

Particularly in rural areas, the Model T had phenomenal success. It was more cost-effective to maintain than a horse-drawn carriage, and it could be easily fixed in the event of damage.

However, the Model T was not just a rural automobile; in the Roaring Twenties, it was the “automobile,” and celebrities in Hollywood clamored for one. Therefore, the “little black car” was featured in many films. The Model T was extensively used in special effects since it was simple to modify and was almost indestructible. The car was often cast as the third lead alongside Stan Laurel and Oliver Hardy in movies. And it was the flying automobile in the Disney comedy “The Absent-Minded Professor,” released in 1961.

According to the Internet Movie Cars Database, the Model T has been featured in over 200 movies to date. East of Eden (1955), Paper Moon (1972), and The Color Purple (1985) are just a few examples. The Model T has also appeared in newer films like O Brother, Where Art Thou? (2000), There Will Be Blood (2007), Jungle Cruise (2021), or The Sandman (2022).

The end of Model T

However, despite the popularity of the Model T, its production almost bankrupted Henry Ford. Competitors had already begun producing automobiles in the 1920s that were quicker, more comfortable, and more stylish than the Model T, while Ford was busy perfecting his manufacturing procedures.

General Motors, in particular, exerted pressure on Ford and ultimately dislodged it from its unquestioned leadership position in the automobile industry by unifying many brands and, by extension, target groups under one corporate roof at an early date. Ford found itself in a bind when it attempted to switch to a new model and discovered that much of its machinery was useless for making other models. For many months, production halted at Ford facilities, virtually bringing the business to its knees. The debut of the brand-new Model A was delayed until October 1927.

When Ford stopped making the Model T in 1927, over half of all cars in the United States were made by the Ford. There are still over a 100,000 Ford Model Ts in circulation today.

After almost 115 years of its introduction, there are still Model Ts around parades through the streets driven by fans. So, they’re still going strong, perhaps for a lot longer than Henry Ford anticipated.