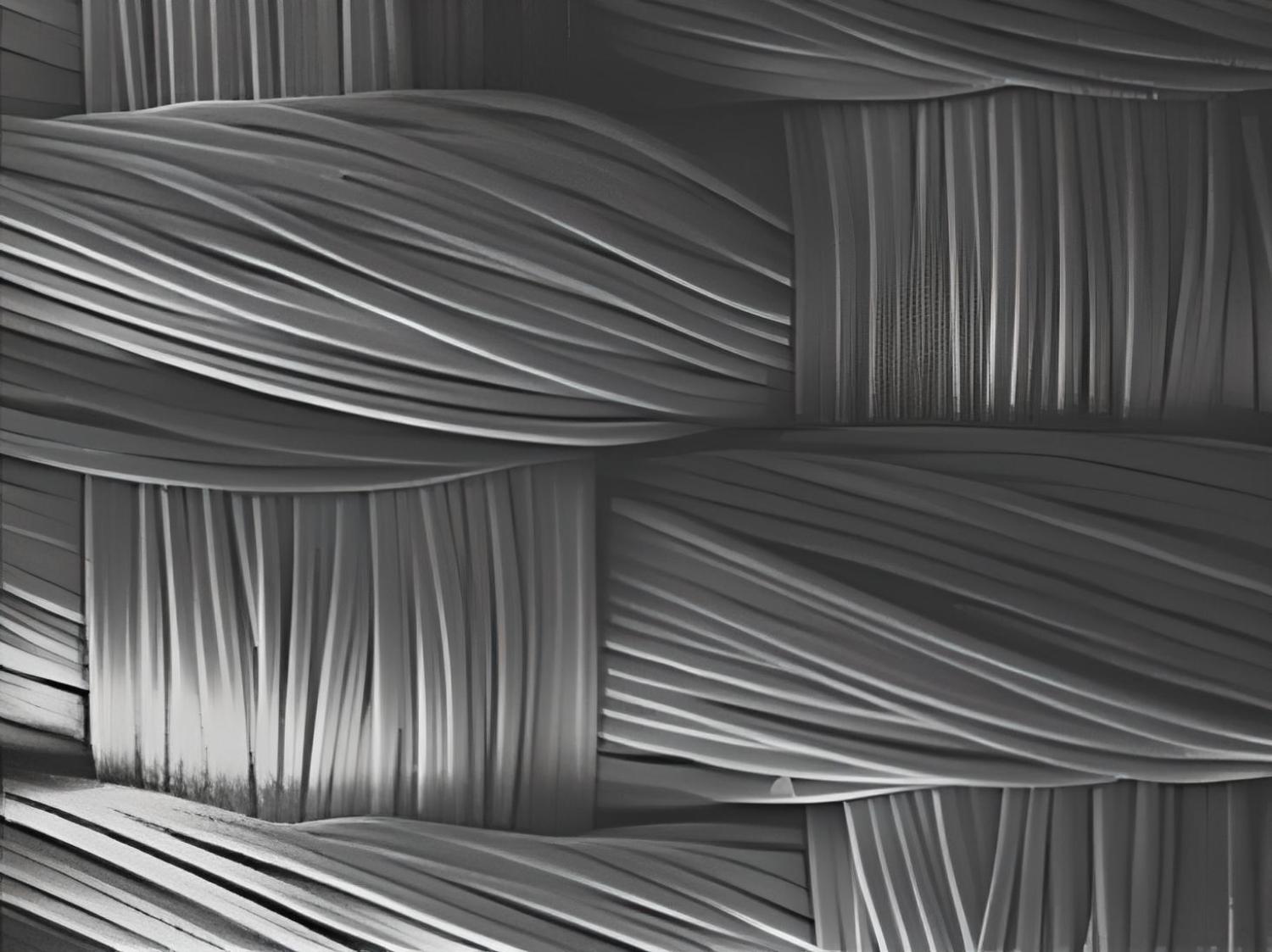

There is a synergy between the ironing elements of pressure, heat, and moisture. While the material’s inherent characteristics do allow for some smoothing, it is the fiber structure of the fabric that allows the steam in particular to have its greatest impact.

Garments with a natural drape have been a go-to for human comfort for generations. To counteract the creases that naturally appear in fabrics after daily use, sophisticated and rather disruptive treatments have been developed throughout time. While ironing may not be everyone’s favorite thing to do, modern electric irons make the process much easier: just plug in the machine, apply some pressure, and let the steam do the rest. Skill determines the outcome of every other factor.

To effectively iron, you need moisture, heat, and pressure. The first need comes as no surprise, given the extensive research done on the positive effects of moisture and warmth on the organism. These suggest that breaking the chemical connections between the long-chain polymers in the fabric is the key. The coiled fibers are straightened out by applying heat and pressure. Due to its ability to weaken intermolecular bonds, moisture is a useful aid in many processes.

Self-wrinkling by steam

But for a very long time, crucial issues remained unresolved. In this example, it was not obvious whether the fine structure of the fabric itself or the nature of the garment’s material had the greater impact on the effect of moisture. It wasn’t until 2012 that a French study team looked at this more. The research group headed by Adrien Benusiglio began by studying the onset and resolution of a single wrinkle in an unprocessed polyester film.

Due to the prevalence of such plastics in the production of commonplace textiles, this serves as a reasonably typical example. The film was exposed to replicable settings where it was given an opening angle and then left to its own devices. The material itself determined how quickly the wrinkle disappeared, which was not affected by gravity. There is a continuity between the dynamics of wrinkles in a single thread and those in a fabric woven from that thread. The elasticity of the material’s restoring force has a significant role in determining its behavior.

Subsequently, folds in the film and the fibrous fabric were introduced to a moisture chamber, where the concentration of water vapor was gradually increased. The higher the moisture content of the fabric, the quicker they are presently bending back. Contrarily, the presence of a single, microscopic-fine fiber had no impact on the unfolding rate of the unwoven material.

Therefore, the impact of the water vapor was attributable to the weave structure rather than any changes in the characteristics of the individual threads, at least in the polyesters examined. Cotton or linen fibers absorb water, making them more pliable and presumably aiding the process, in contrast to plastic, which does not absorb water.

In any event, the regions where the fabric’s threads are in touch with one another provide the smoothing impact of moisture. As long as the absolute humidity value is lower than the saturation humidity, water vapor typically does not try to condense. However, unusual circumstances exist within the tiniest of holes. Even if the quantity of water vapor in the free atmosphere is insufficient to cause saturation, some of it may condense into a liquid.

Capillary condensation

Capillary condensation is the name given to this phenomenon, which is caused by the thin capillaries created by the fibers. For liquefaction to take place, there must be an increase in the interactions between the water vapor molecules and the filament walls. In the end, a new equilibrium is reached below the external saturation vapor pressure.

Capillaries are often seen in our minds as tubular, closed forms. Fabrics made from textiles, on the other hand, need not be limited to any one enclosed area. The proximity of the wettable surfaces is the critical factor in both cases, but the result is the same. There is a greater need for water molecules to interact with the surface due to the increased crowding at the microscopic level. Reducing the saturation vapor pressure is impossible without it. Capillary condensation is an exquisite illustration of the generalizability of phenomena occurring on the nanoscale and micrometer scale to the macroscopic world.

Benusiglio’s article did not go into the topic of temperature any further. The study team, however, believes it to be feasible that both elastic unfolding and capillary condensation become more pronounced with increasing temperature.

When the air is humid enough

The clothes you bring on your trips will last better if there is a good amount of humidity in the air, as any frequent flyer will tell you. If you hang your wrinkled clothes in the hotel bathroom overnight, you can generally find them at least somewhat ironed the following morning. That’s why most clothing doesn’t wrinkle much when worn, too. Due to its proximity to the body, its moisture and warmth help bring many fine lines and wrinkles back to their original, smooth state.