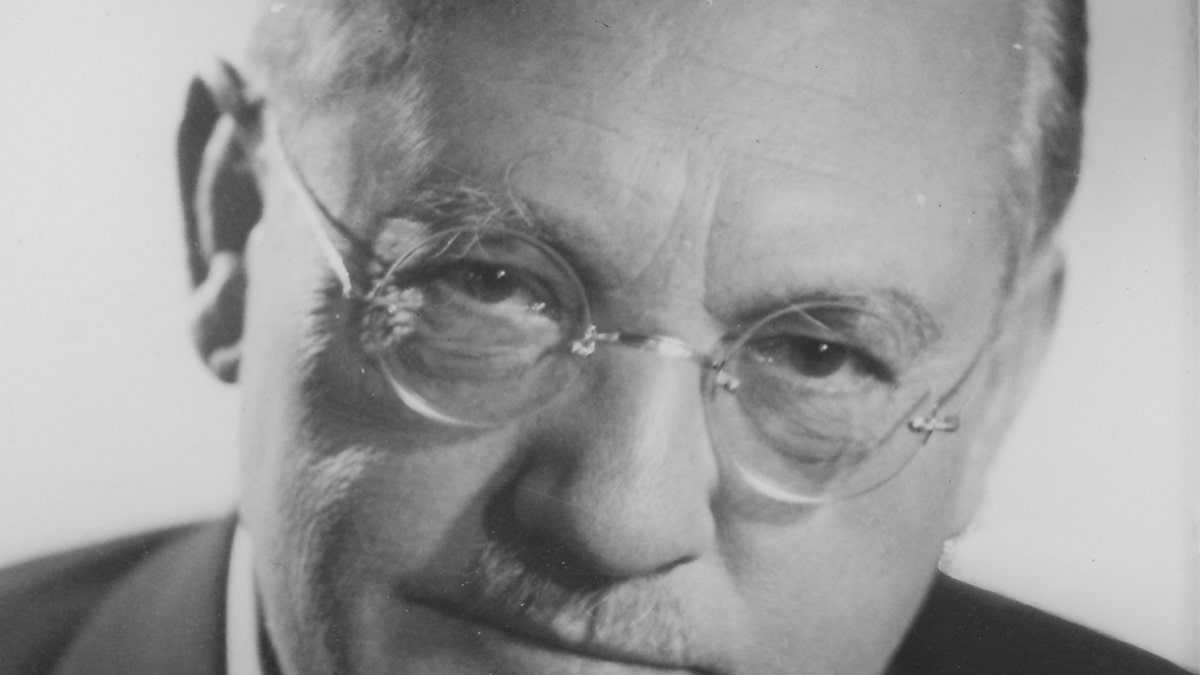

Perhaps the most profoundly influential invention in the 20th century was neither the machine nor a device. The German chemist Carl Bosch found a way to produce synthetic ammonia, which led to the mass production of explosives and chemical fertilizers on a scale never seen before. This resulted in unlimited explosive capacity in both world wars and, ironically, a world population explosion.

Who is Carl Bosch?

Carl Bosch was born in Cologne, Germany. He studied mechanical engineering and metallurgy at the Technical University of Charlottenburg. In 1896, he began studying chemistry at the University of Leipzig. Three years later, Bosch joined Germany’s most successful chemical company in Ludwigshafen. The company’s name at the time was Badische Anilin- und Sodafabrik, which is now simply known as BASF.

Initially, Bosch was interested in synthetic dye. However, in 1905, his attention was directed to a crucial problem of the time: how could atmospheric nitrogen be “fixed” to the chemical components? At first, the problem seemed to concern a small environment, but in fact, its global significance was enormous. In the 19th century, scientists found that nitrogen-rich compounds were highly effective fertilizers. High amounts of guano (petrified feces) and saltpeter (potassium nitrate, KNO3), in particular, helped the world’s population grow in a way that was sustainable.

In 1898, the English chemist William Crookes (1832–1919) pointed out the gradually diminishing wheat resources, in his presentation for the British Association, entitled “The Wheat Problem.”

He also warned that the world could face famine in the 1920s. Moreover, nitrogenous compounds were also a main component of explosives. In the early years of the 20th century, the rising threat of war brought new demands for nitrogenous compounds.

Nitrogen rarely reacts with any other elements. This is why it makes up about 80% of the atmosphere. Beginning in the 1890s, chemists tried in vain to find an effective and highly efficient chemical process to “fix” nitrogen in the air to make fertilizers and explosives. Later in 1905, the German chemist Fritz Haber (1868–1934) said that he had made a small amount of ammonia from hydrogen gas (H2) and nitrogen gas (N2).

Haber-Bosch process

Haber’s approach required high temperatures, high pressures, and a catalyst (a substance that accelerates a reaction or reduces the energy required for the reaction to take place without itself undergoing any changes). Haber was working at BASF, and in 1909 he obtained a large amount of ammonia in his laboratory. In the same year, BASF assigned Bosch the task of improving Haber’s reaction to enable it to be used on an industrial scale.

Carl Bosch has developed a reactor that can withstand the required high pressures and temperatures. This was a special double-walled chamber that was more convenient and safe than Haber’s system. Bosch has conducted nearly 20,000 experiments in the search for a more suitable catalyst compared to Haber’s high-cost osmium and uranium. Bosch also explored methods of obtaining large amounts of nitrogen and hydrogen from the air by passing steam through hot coke coal. As a result of his studies, he obtained a patent in 1910. In 1911, a large amount of ammonia was produced at BASF.

Only two years later, the company opened the world’s first ammonia-only plant in Ludwigshafen’s village of Oppau. Ammonia was largely used in the production of artificial fertilizers. However, when World War I broke out in 1914 and the German government faced an ammunition shortage, Oppau used the plant only to produce explosives. Without the accomplishments of the Haber-Bosch duo, the war would probably not have lasted that long. Britain imposed an embargo so that Germany could not import the saltpeter needed to make the explosives.

Bosch’s extensive work and deep knowledge in the fields of chemistry and engineering paved the way for large-scale, high-pressure production. This development would strengthen the modern chemical industry. In 1931, Bosch was awarded the Nobel Prize in Chemistry. Today, around 200 million tons of artificial nitrogen fertilizer are produced annually worldwide using the Haber-Bosch process.

Fertilizers

Carl Bosch made it possible to produce a large amount of ammonia, which was made from nitrogen-rich ammonium nitrate (NH4 NO3) fertilizers. It is estimated that about half of the world’s population feeds themselves through synthetic fertilizers. Plants need nitrogenous compounds to produce protein and DNA (deoxyribonucleic acid). In nature, nitrates are obtained from decaying plant and animal residues and some bacteria that can fix nitrogen in the atmosphere.

On the other hand, Bosch’s legacy is a double-edged knife. Artificial fertilizers prevented millions of people from starvation, but the world population increased from 1.8 (in 1910) to 7 billion in just 100 years, and now Earth’s resources are running out faster than nature can replenish them.

Approximately 1% of the world’s energy consumption is spent on the production of these fertilizers, while their use leads to pollution. In particular, surface waters flowing from agricultural areas cause “harmful algae explosions” due to excessive nitrogen in lakes and river mouths.