This is the timeline of the engine—the progression of its history. Engines burn fuel to produce hot gas. This gas, in turn, expands powerfully, generating the force that keeps the parts moving. Engines have evolved over the centuries, taking different forms, from steam engines to rotary engines to gas turbines. The engine’s significance in driving the industrial revolution and creating the modern world is inextricably intertwined with the development of human society.

- The Invention and Evolution of the Engine

- 1st Century AD – Aeolipile

- 1679 – Papin’s Steam Digester

- 1698 – First Steam Engine – Savery Engine

- 1712 – First Engine With Piston and Cylinder – Newcomen Engine

- 1777 – Watt Engine

- 1791 – Barber’s Gas Turbine

- 1799 – First High-pressure Steam Engine – Trevithick Engine

- 1816 – First Closed-System Engine – Stirling Engine

- 1860 – First Gas Engine – Lenoir’s Gas Engine

- 1876 – First Four-Stroke Engine – Otto Engine

- 1897 – First High-Efficiency Engine – Diesel Engine

- 1926 – First Liquid Propellant Rocket

- 1937 – First Jet Engine

- 1956 – First Rotary Engine – Wankel Engine

The Invention and Evolution of the Engine

Ancient Greek thinkers realized 2,400 years ago that heat could move objects. In the 1st century AD, they invented the aeolipile. With this device, steam was sprayed out of a metal sphere, causing it to rotate on a shaft. It took another 1,600 years before another usable steam engine was invented. The big breakthrough came in the 1670s with the discovery of vacuum power. The French inventor Denis Papin realized that steam condenses and shrinks in volume when confined in a cylinder and that this shrinkage produces a partial vacuum sufficient to move objects. In 1698, English inventor Thomas Savery built the first full-size steam engine using this principle.

For 150 years, engines ran on steam power. These engines drove the Industrial Revolution, powering everything from machines to ships and locomotives. Engineers made the internal combustion engine around the middle of the 19th century. They did this by using the sudden explosion of burning gases in a cylinder. These engines were more compact and used oil, not coal, as fuel.

As opposed to coal, which was fed by hand, oil was a more concentrated fuel that automatically delivered itself. The internal combustion engine enabled the creation of the car, revolutionizing transportation in the 20th century. Jet and rocket engines made it possible for planes to fly at speeds that had never been thought of before. This made it possible to send spacecraft to the Moon and beyond.

1st Century AD – Aeolipile

The Alexandrian scholar Hero designed a device in which a sphere was rotated by jets of steam. He called it the aeolipile, and it is the first engine in history. Its construction had no practical purpose other than scientific curiosity, but it was able to rotate continuously, utilizing the power of steam energy.

In the first century AD, the term “aeolipile” was used by the Greek mathematician and inventor Hero of Alexandria to name the oldest known engine in history. When Hero invented the aeolipile, he described this invention in “Pneumatica”.

In his “wind ball,” or aeolipile setup, the water was kept hot in a sealed caldron made of a hollow sphere that was then placed atop a heat source. The sphere was set in spinning motion as steam was propelled out of its equator through bent tubes. The machine converted steam into mechanical energy to spin a ball. The aeolipile is the first known example of a heat-to-mechanical energy converter.

Because of its high cost and the absence of complementary technologies, aeolipile was unable to spark an industrial revolution in the first century AD.

1679 – Papin’s Steam Digester

French inventor Denis Papin invented this steam boiler that trapped steam inside a cylinder. In Papin’s boiler, a vessel with a tight-fitting lid prevented steam from escaping and dramatically raised the boiling point of water. As the steam condensed, cooled down, and shrank in size, this steam digester created a strong vacuum.

Papin’s invention, a high-pressure steam device for extracting fats from bones, making the bones brittle, and turning them into bone meal, laid the foundation for the modern autoclave, hence the invention’s other name, “bone digester.”

Denis Papin also invented a safety valve that released the steam to avoid explosions. Papin envisioned a piston and cylinder engine while observing the valve’s up and down movement but did not pursue the design. Later, Thomas Savery independently created the first steam engine in 1697 and Thomas Newcomen improved upon the design with Papin’s concept in 1712.

1698 – First Steam Engine – Savery Engine

Thomas Savery built the first steam engine. This engine was used to pump water out of mines. But the device could easily explode. The Savery engine was the first widely used steam-powered device, a pump that made public water supply more feasible. It was a new invention for raising water and powering mills by the force of fire. The steam from boiling water was collected in a tank, and the vacuum was created by removing the tank from the steam source and allowing the steam to condense. This was how Savery’s pump operated. Only shallow water would be sucked up by this vacuum.

The process of operation involved heating water in a boiler to create steam, which was then directed into a working vessel. The steam was expelled through a downpipe, lifting water from the mine. The tap between the boiler and the vessel was closed and cooled to condense the steam and create a vacuum, allowing atmospheric pressure to fill the vessel with water. The tap was then opened between the vessel and the up-pipe, and more steam was admitted, pushing the water up to the top of the mine. The pump had four main issues: the heat was wasted during the pumping process, the pump’s joints couldn’t withstand high-pressure steam and needed frequent repairs, it could only pump water to a limited height and it had to be placed deep in the mine.

Unlike the later Newcomen steam engine, Savery’s pump had no moving parts and was more affordable, costing between 150-200 GBP for a 2- to 4-horsepower pump. Despite the advancements and bigger sizes of the piston steam engines, Savery-type pumps were still produced in the late 18th century due to their practicality.

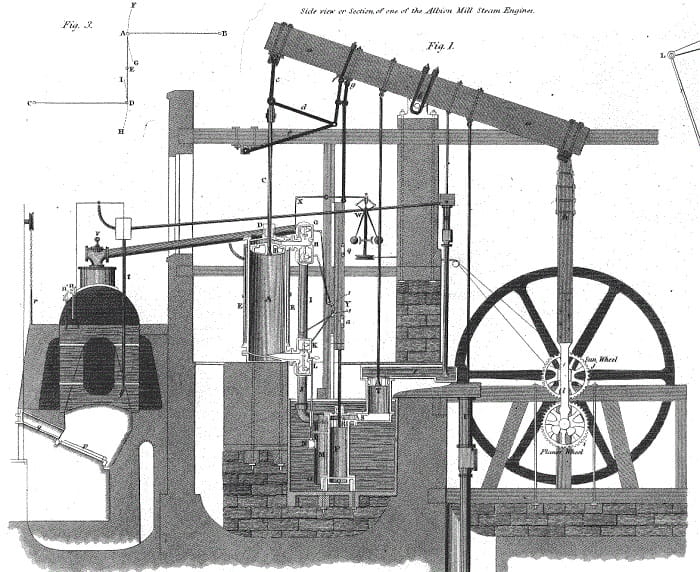

1712 – First Engine With Piston and Cylinder – Newcomen Engine

The Newcomen engine was the first engine to use a piston and cylinder. Thomas Newcomen, a British inventor, invented a steam engine in 1712 which he prevented from exploding by boiling water in a separate part of the engine. He then used the steam generated to power a piston cylinder at low pressure. The Newcomen engine is the first atmospheric engine in history.

Thomas Newcomen’s design for a steam engine included a movable piston housed in an open cylinder. Piston chains led to a rocking beam, which in turn led to a rod that powered the mine’s water pump. The engine worked by first introducing steam from the boiler into the cylinder, which condensed when exposed to cold water. The water pump’s plunger was raised because the rocking beam was sucked into the resulting vacuum formed by the descending piston. The vacuum is created when water that has turned to steam is condensed back into water as its volume decreases by a factor of 1500, creating an empty vacuum inside the area.

Despite their worse fuel efficiency compared to that of a newer Watt engine, Newcomen-style engines were still in use in the 19th century, all the way to 1923. Possible contributing factors include the availability of fuel and the convenience of making a lump-sum payment to Newcomen rather than a recurring payment for the Watt engine to obtain a license and utilize their technology. A single Newcomen engine from 1811 was a towering 31 ft (9.5 m) in height, 31 ft (9.5 m) in length, 148 ft (45 m) in width, and weighed a hefty 20 tons. It was constructed from cast iron and wood.

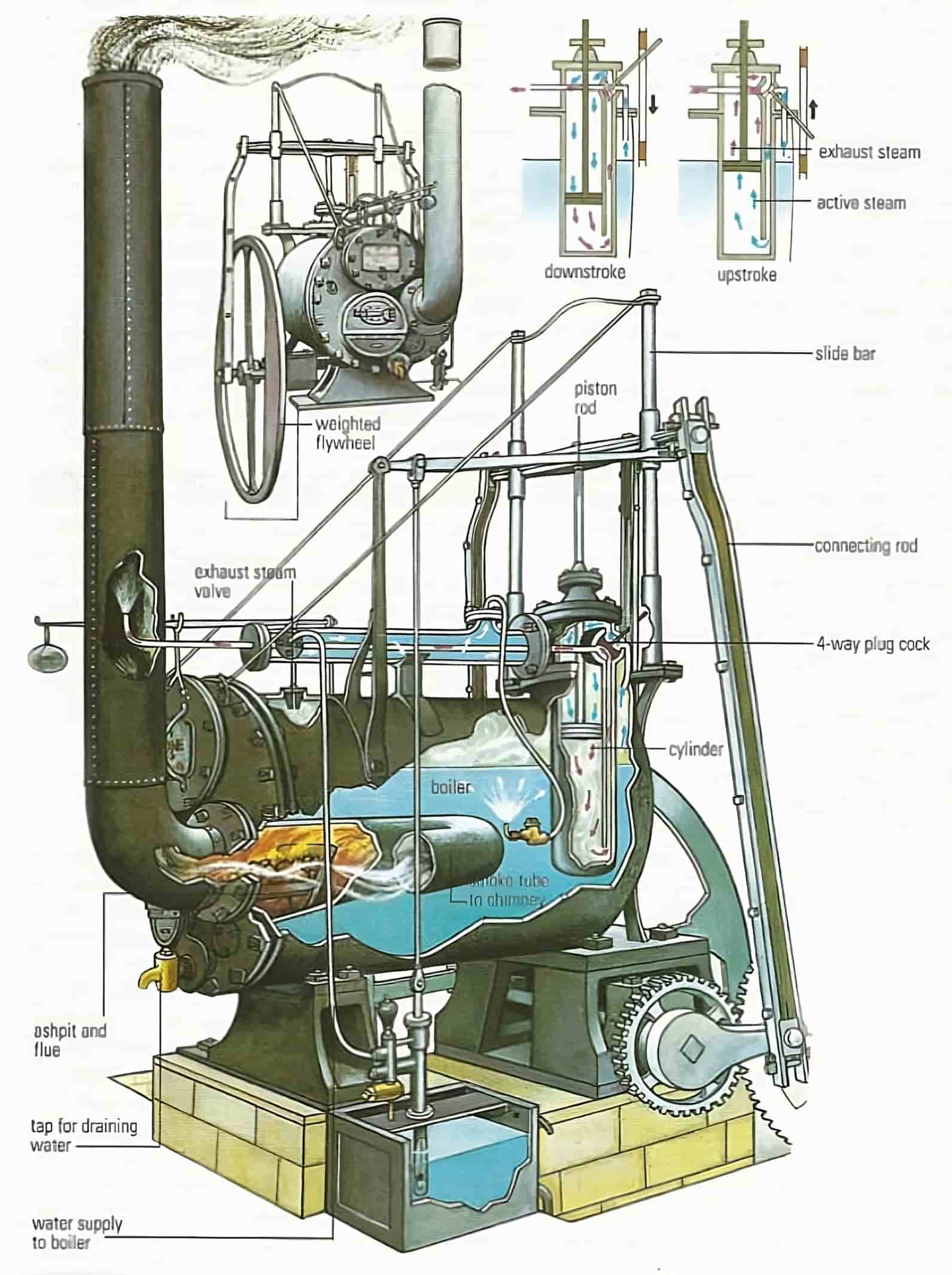

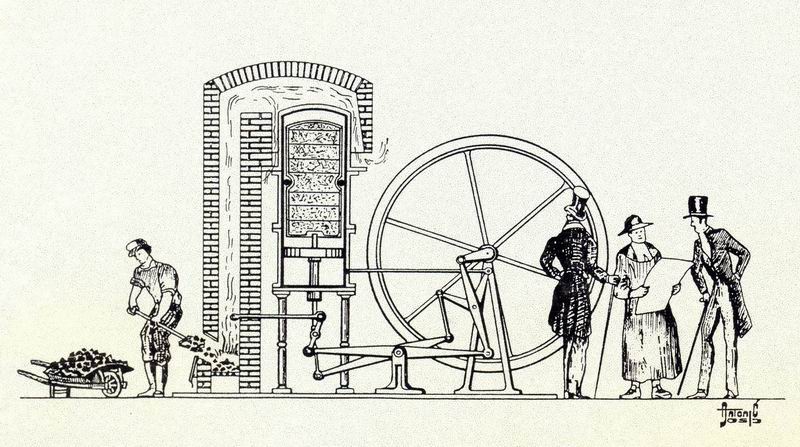

1777 – Watt Engine

Scottish engineer James Watt built an improved steam engine. This engine had a separate condensing chamber and was more efficient. Thus, the condensation processes were isolated to a permanently cold area. As a result, the rapid condensation of steam maintained a constant high temperature in the cylinder. When compared to the Newcomen engine and its predecessors, Watt’s engine was two times as quick.

In 1763, Watt was charged with repairing a model steam engine by an Englishman. It was based on Thomas Newcomen’s engine, who first built it in 1712. Intended to be used to remove water from mines, it was much too inefficient for that purpose. Watt immediately figured out the issue: The steam was cooling down in the cylinder, resulting in a large waste of energy. Watt envisioned a more efficient machine that used less coal and generated more energy.

Between 1786 and 1885, many Watt steam engines were constructed by James Watt out of 20 tons of wood in Southwark, London, England. Today, power is measured in watts, which was named after James Watt. The first Boulton & Watt engine was invented in 1786 to pump water. By 1796, it was modified to not only pump water but also grind barley simultaneously. This made it unique, as no other steam engine at that time could perform both functions.

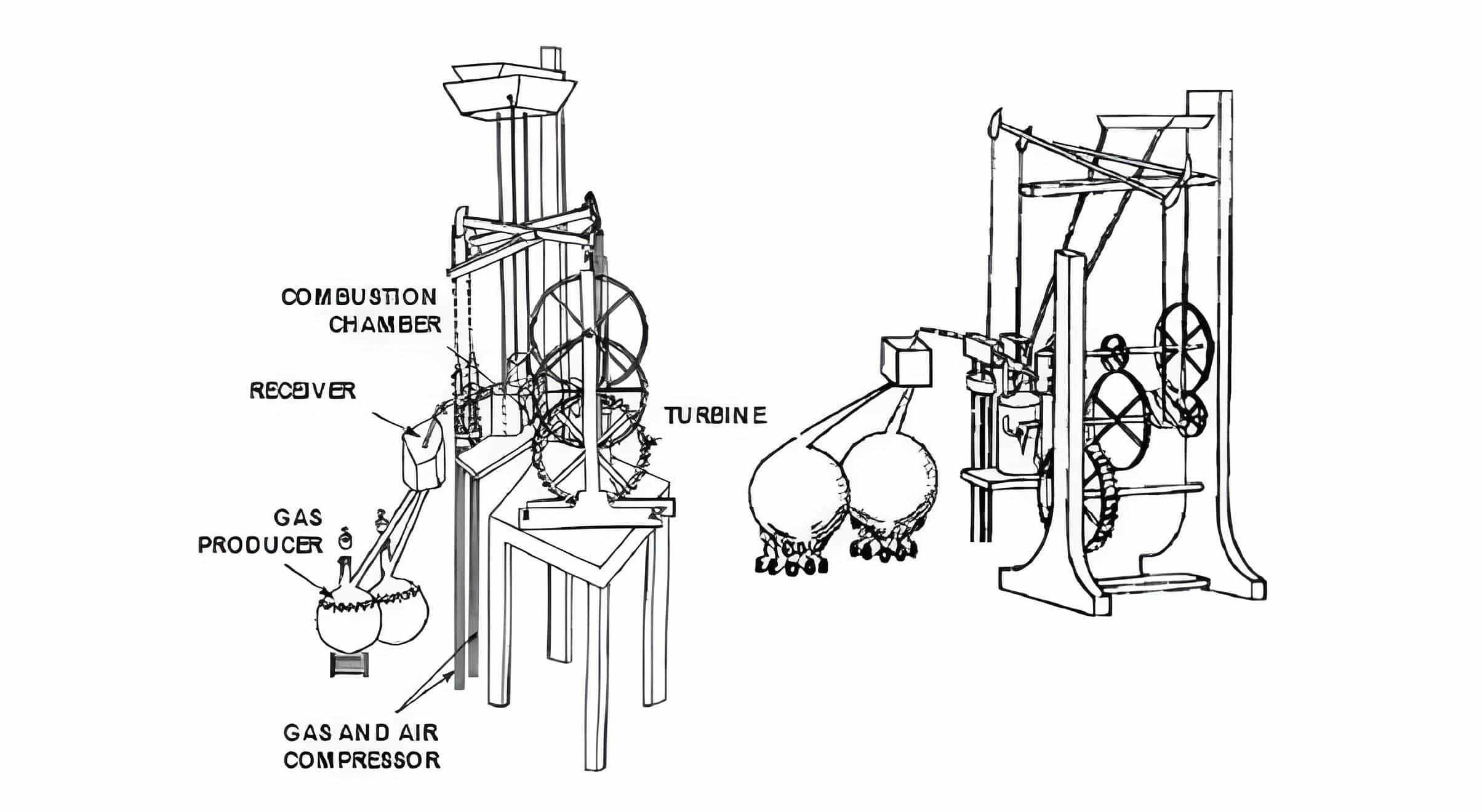

1791 – Barber’s Gas Turbine

The English inventor John Barber patented a gas turbine. The purpose of this gas turbine was to make a “horseless carriage.” In this device, fuel is mixed with air and ignited to produce hot gas, which drives the turbine.

Between 1766 and 1792, John Barber received many patents, one of which was for the first functional gas turbine. Eventually, a functional prototype based on Barber’s concept was built. Barber was the first to fully describe the gas turbine idea, and his innovation predated contemporary gas turbines by many decades. Barber’s proposal paved the way for the current gas turbine, even if existing technology at the time prevented it from producing enough power.

Gas was first heated and then cooled in a receiver before being utilized in Barber’s turbine; the gas might have come from any number of different sources, including wood, coal, or oil. The compressed air and gas mixture was then fed into a combustion chamber called an “exploder” and set ablaze. The vanes of a paddle wheel were then exposed to the scalding gas. The chamber was cooled with water, and steam was used to propel the charge.

A comparable idea for jet propulsion was invented by Sir Frank Whittle in 1930, and its first practical application was in 1937. Like other forerunners in the area, he built upon the foundation laid by people like John Barber.

1799 – First High-pressure Steam Engine – Trevithick Engine

Initially labeled “slow,” Richard Trevithick (1771–1833) became known for his ability to solve difficult mechanical problems, and he began working as an engineer in the ore mines in 1790, at age 19. Low-pressure, vacuum-based engines were large and heavy. So, the British engineer created a compact and powerful high-pressure steam engine. By the beginning of the 19th century, Richard Trevithick had invented both a high-pressure steam engine and a working steam locomotive.

James Watt’s low-pressure steam engine was widely used at the time, but Trevithick believed he could create a smaller and more effective engine by using high-pressure steam and allowing it to expand within the cylinder. Trevithick achieved that in 1799 with his “Trevithick engine.” He built working replicas of stationary and locomotive machinery with high pressure, and in 1801 he even built and drove the first steam-powered vehicle. In 1803, Trevithick constructed the world’s first steam locomotive, and in 1808, he showed off his famous “Catch-me-who-can” locomotive with 20 mph (32 km/h) top speed and 240 miles (390 km) range.

He subsequently used his high-pressure engine in several different ways, including propelling a paddle-wheeled barge and operating an iron-rolling mill. His breakthroughs in boiler design and construction allowed for the creation of the well-known Cornish-type boiler, which was used in conjunction with the similarly well-known and effective Cornish pumping engine.

1816 – First Closed-System Engine – Stirling Engine

In 1816, the Scottish engineer Robert Stirling invented a steam engine in which the gas remained inside the system. The Stirling engine is a type of heat engine that converts thermal energy into mechanical work by the repeated compression and expansion of a working fluid, often air or another gas. The lack of air intake and exhaust gas outflows meant that the gas was not released and that there was less noise from the explosions. So, it was a steam engine without steam.

The regenerator in this closed-cycle engine momentarily stores heat, boosting the engine’s efficiency. In the Stirling engine, gas is heated and expanded by an external energy source and then pushed by a piston. First, the gas is carried to a position where it can be cooled and compressed, and then the piston moves it back to the region where it will be heated. Gas’ natural tendency to undergo temperature and pressure fluctuations is used to generate mechanical energy.

Robert Stirling’s original intent was to provide an alternative to the steam engine, but its practical applicability ended up being restricted to low-power residential uses. When compared to conventional internal combustion engines like those that run on gasoline or diesel, the Stirling engine has the potential to be far more efficient. These days, it is mostly employed in submarines or boats with auxiliary power generators.

1860 – First Gas Engine – Lenoir’s Gas Engine

The Belgian-French engineer Jean Joseph Etienne Lenoir invented the first successful internal combustion engine, the gas engine. The gas engine generates power by burning gas and air in a cylinder. The whole engine was about 6.9 feet, or 2.1 meters, in length. In 1860, Etienne Lenoir received a patent for a gas engine with a single cylinder that could perform two strokes at once.

At each stroke, the engine sucked in fuel and air with slide valves and set it ablaze with an electric spark, much like a double-acting steam engine. On the upstroke, the exhaust of the burned gases was released. The 18-liter Lenoir engine could barely produce 2 horsepower.

These engines were sold in the hundreds. The steam engine was 4% efficient in fuel consumption but had smooth operation and durability. It was widely used for low-power tasks such as pumping and printing by 1865, with hundreds of them in use in France and 1,000 in Britain, even lasting for two decades in some cases.

1876 – First Four-Stroke Engine – Otto Engine

On May 9, 1876, German inventor Nicolaus Otto constructed the first compressed-charge internal combustion engine after more than a decade of labor. The Otto engine had a single cylinder, a four-stroke internal combustion engine, and it fired every other stroke.

German engineer Nicolaus Otto’s (1832–1891) powerful four-stroke engine fired the cylinder four times per cycle so that the fuel ignited inside each one and pushed the piston every four strokes. The mixture was squeezed into a horizontal cylinder using a piston, and then ignited just before the piston reached the top.

Through the use of fuel mixture layers and the prevention of explosions, Otto was able to produce controlled combustion and increase piston push in the cylinder. To keep the engine from blowing up, Otto devised a method of layering the fuel mixture into the cylinder, causing the fuel to burn at a progressive rather than explosive pace.

The maximum horsepower output of an engine was never more than 3 until the invention of the Otto engine in 1876. And only in 1920 did the engine output increase to 1000 horsepower with the Napier Cub aircraft engine. While the Otto engine remained confined to lighter fuels, the subsequent innovations such as the Diesel engine were able to burn heavier fuels and lubricants.

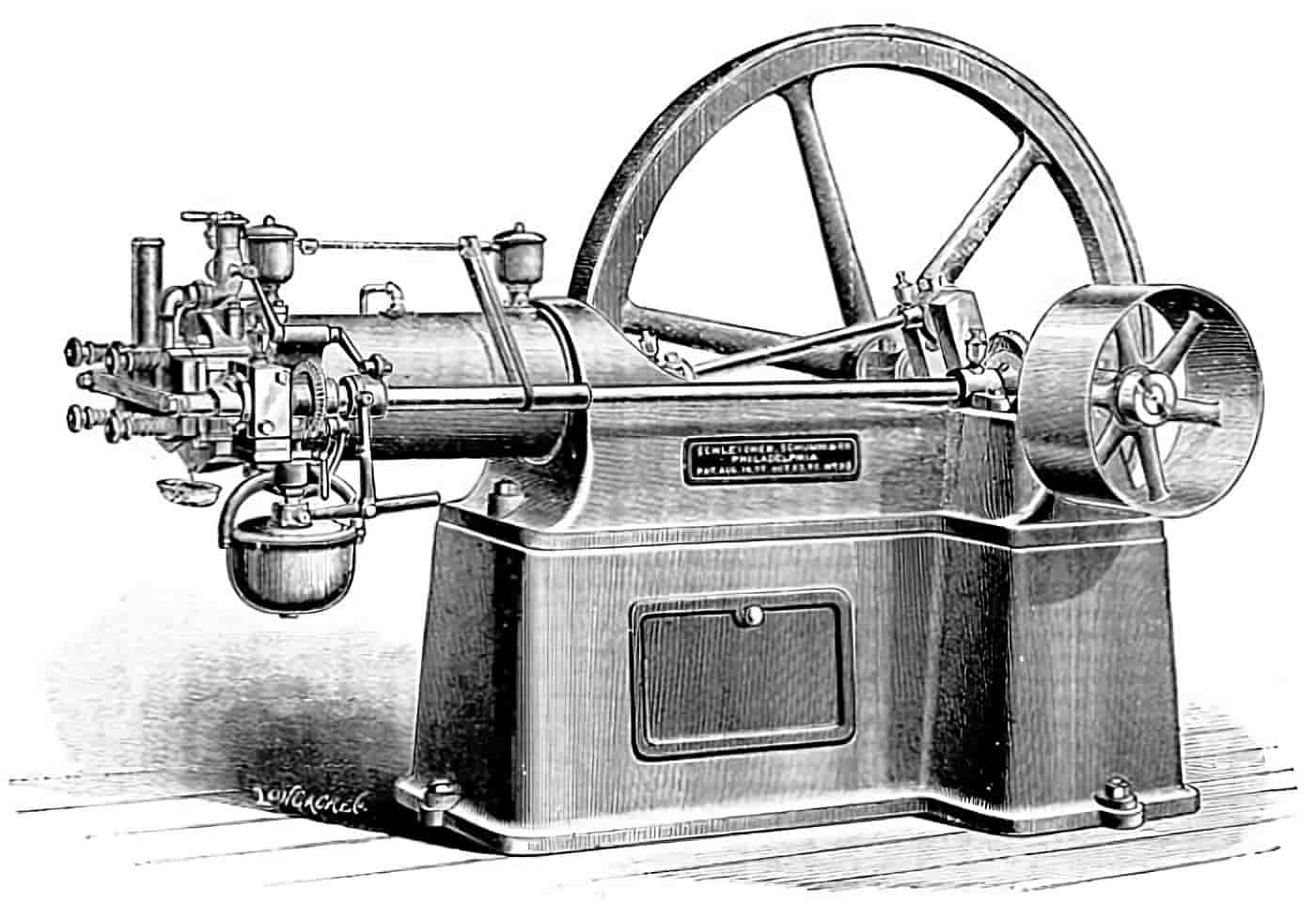

1897 – First High-Efficiency Engine – Diesel Engine

The first diesel engine was built by Franco-German engineer Rudolf Diesel (1858–1913) in 1897. Even though the invention was heavier than petroleum engines, it was more efficient, and the fuel was ignited by the heat of the compressed hot air instead of an electric spark like gasoline-powered Otto cycles. His compression-ignition internal combustion engine was supposed to be a better alternative to conventional steam engines.

Steam engines were the standard in the late 1800s, despite being expensive and inefficient. Diesel, via his research into thermodynamics, found a means to create an internal combustion engine that would utilize all the heat produced.

After some early difficulties, his engine was finally shown in 1897 after being refined and tested to an efficiency of around 26%. When compared to the best steam engine of the time, this was almost three times more efficient. After more than a decade of research and trials, US Patent No. 608,845A for an “Internal Combustion Engine” was issued to Rudolf Diesel on August 9, 1898. The diesel engine was a huge leap forward in the timeline of the evolution of engines.

Diesel engines eventually became popular in the military, especially in submarines since diesel fuel is less explosive than regular gasoline. Diesel, however, continued to have money problems as a result of customer complaints about the poor reliability of his engines. He is believed to have been murdered while traveling aboard a ship to negotiate a deal with the British Navy.

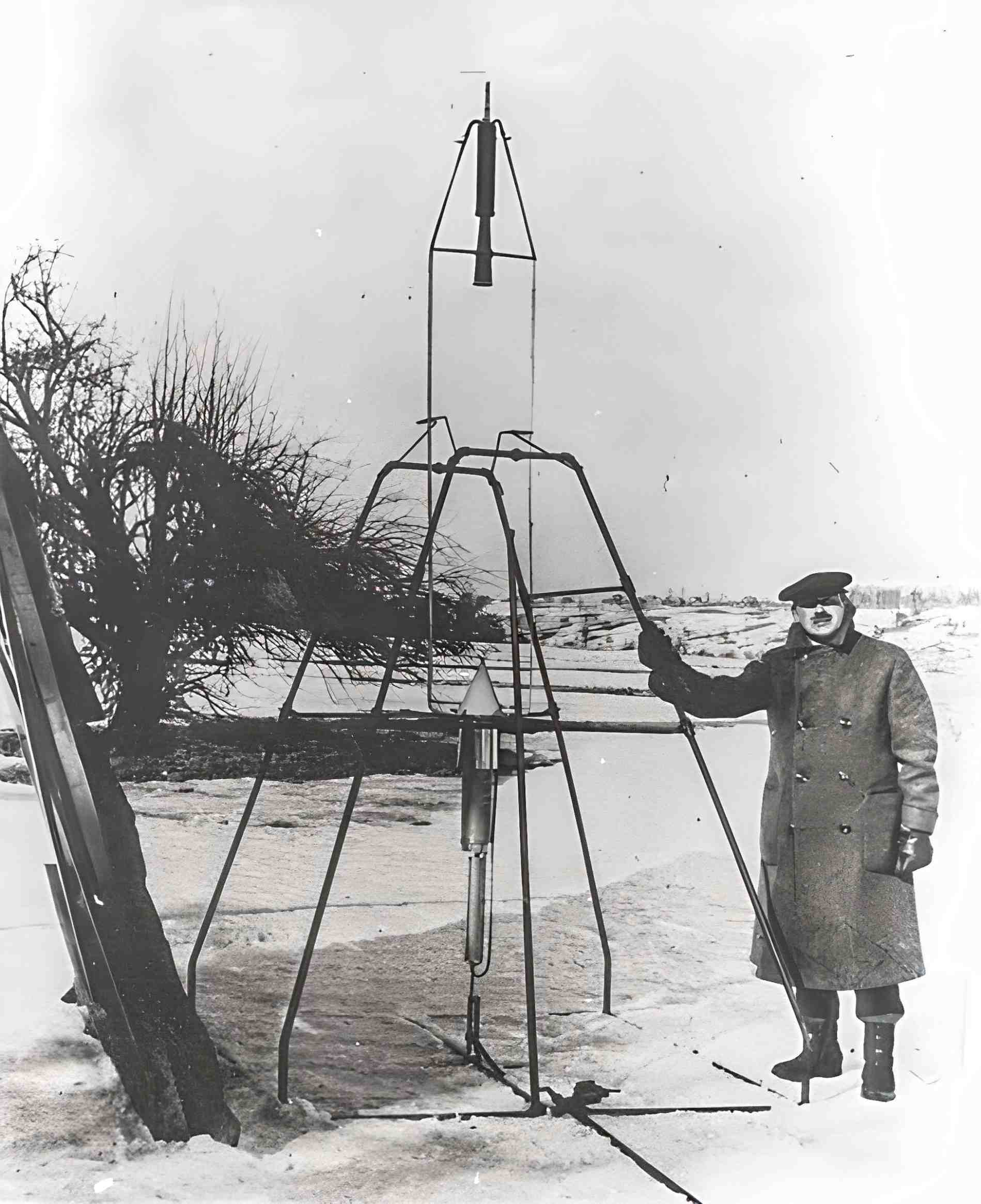

1926 – First Liquid Propellant Rocket

When the first rocket flight in history happened on March 16, 1926, it flew for 2 seconds at an average speed of roughly 60 miles per hour and reached a height of 41 feet.

American engineer Robert Goddard (1882–1945) invented the rocket engine. In this engine, the thrust required for flight is generated by the combustion of liquid fuel. Goddard experimented with a gunpowder-powered rocket as a student at Worcester Polytechnic Institute in Massachusetts in 1907. The clouds of smoke he produced attracted the attention of the instructors, who decided to support his work rather than kick him.

Rocket propulsion is an area of study today in which Clark University scientist and professor Robert Goddard made the first significant contributions. Goddard determined the potential energy and thrust of different fuels, establishing for the first time that rockets could be used in zero-gravity conditions. He was awarded patents for his innovative ideas about multistage rockets and liquid-fueled rockets. In 1926, he successfully launched the first liquid-fueled rocket, building on the groundwork he had created in the 1920s. Some scientists doubted and mocked Goddard despite his ground-breaking research.

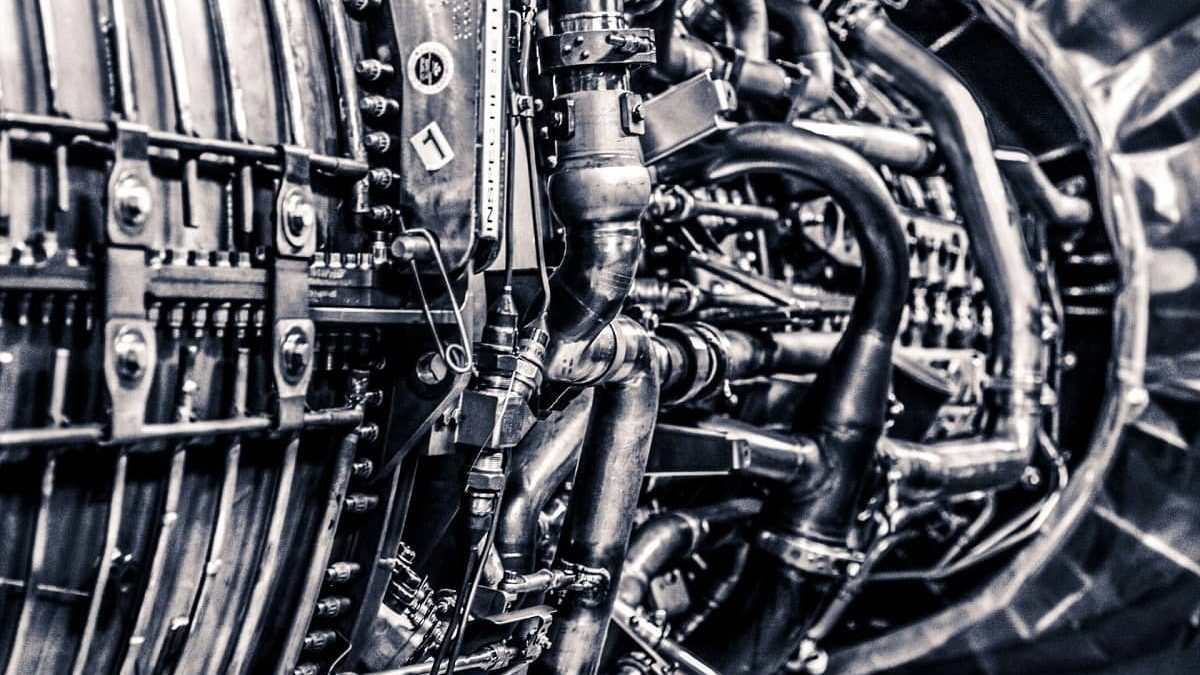

1937 – First Jet Engine

British engineer Frank Whittle (1907–1996) and German engineer Hans von Ohain (1911–1998) independently invented and tested the jet engine. This device burned fuel to propel the aircraft forward and continuously blasted hot air through a fan.

Although the first patent for a gas turbine to power an aircraft was submitted in 1921 by the Frenchman Maxime Guillaume, the project was never realized. Sir Frank Whittle, a British engineer, received a patent for his ground-breaking jet engine in 1932. The Whittle jet engine first ran on April 12, 1937 and thus, it was the first jet engine to operate on liquid fuel.

In the meantime, a jet engine with an axial-flow design was invented in 1935 by German inventor Hans von Ohain. The first jet airplane, the turbojet-powered German Heinkel He 178, took to the skies in August of 1939. In the 1950s, jet engines with axial-flow designs were widely embraced by the manufacturing industry.

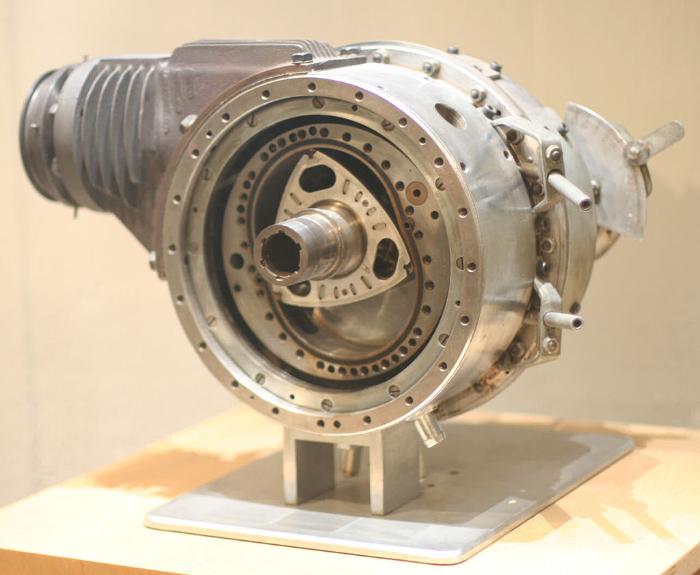

1956 – First Rotary Engine – Wankel Engine

German engineer Felix Wankel (1902–1988) created a rotary engine. This engine featured a rectangular cylinder instead of a triangular rotor and piston. In 1954, Wankel finished designing a rotary-piston engine, and by 1957, the first prototype had been tested. His rotary engine is most often used in racing cars. The Mazda RX-8 sports car used a Wankel engine until the car was discontinued in 2012.

In 1924, Wankel established a lab to research and build an improved gasoline internal combustion engine he had come up with as a teenager. The pistons in standard internal combustion engines move up and down in cylinders, but the Wankel engine has a completely different architecture.

The Wankel engine has a triangular rotor that spins within a sealed chamber and performs the four actions of an internal combustion engine—intake, compression, expansion, and exhaust—in a single cycle. This layout has a lot of pros, such as being easy to move, cheap, needing little maintenance, being light, and having a small footprint.