The shift from an agricultural-based economy to one based on automated, mass production of manufactured products began around the close of the 18th century with the advent of the Industrial Revolution. Innovations in technology and the availability of alternative energies aided this process. The phenomenon of the Industrial Revolution happened at various periods in each nation, marking the beginning of a significant social mutation and the emergence of a working class. Unlike England, Germany, and the United States, France’s industrial development in the 19th century was steady and significant rather than spectacular and marked by a period of abrupt acceleration.

The Industrial Revolution saw a multitude of technological innovations, including the steam engine, spinning jenny, power loom, telegraph, and the railroad. These inventions transformed various industries and modes of communication.

England: The Pioneer

Beginning in late 18th-century Britain, the first industrial revolution spread around the world. Both the British economy and social structure were drastically altered. The most noticeable changes occurred in production’s basic characteristics, as well as its mode and location. The primary product sector lost workers to the manufactured goods and services sectors. The creation of more sophisticated and productive machinery, like James Watt‘s steam engine, greatly boosted the output of produced goods.

The systematic incorporation of both theoretical and empirical understanding of the manufacturing process also contributed to the productivity increase. Finally, it was found that concentrations of businesses in small areas were more productive. Thus, rural-to-urban migration and transnational movement from rural to urban places were connected to the industrial revolution.

Some of the most noticeable shifts occurred in how labor is structured. The organization grew and added new capabilities. Instead of doing so within the context of a lord’s realm or by specific family members, the company now handled production. Regularity and specialization increased as the workload increased. The utilization of capital increased dramatically in industrial output. Workers were able to crank out far more products because of the advent of cutting equipment and mechanized assembly lines. This tendency toward specialization was bolstered by the benefits of expertise in a certain activity (the production of a specific component or instrument).

Additional divisions between social classes emerged as a result of the Industrial Revolution’s increased reliance on specialized labor and massive capital investments. A large industrial and possessing bourgeoisie, owner of the means of production, whose members became known as “capitalists,” and a class of workers concentrated in manufacturing and heavy industries, who quickly formed a very homogeneous social class, brought the “social question” to the forefront of political debate at the end of the 19th century.

Prosperous Growth in the Economy

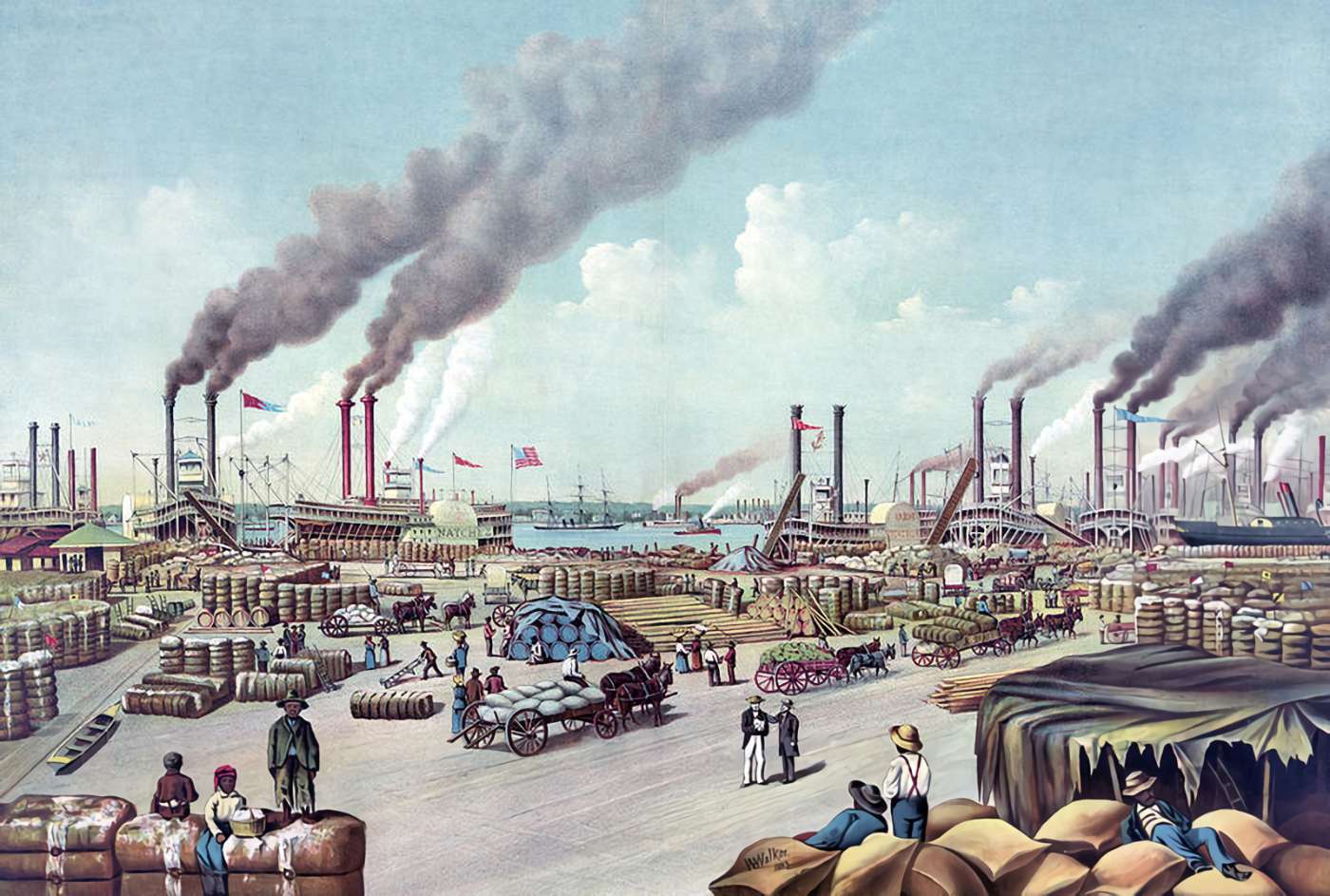

Britain was the experimental ground for a major economic and social shift since it was where the first industrial revolution took place. London was the hub of a global commercial network that facilitated the growing export of industrialization-era commodities for the majority of the 18th and 19th centuries. Exports, capitalizing on the reach of the British Empire, were critical to supporting the booming textile and industrial sectors driven by technological advances.

Exports from Britain grew rapidly after 1780, according to available statistics, and the economy did well overall. Increasing exports and access to global markets benefited the economy in two ways: first, manufacturers were able to afford the low-cost raw materials (obtained from the colonies) they needed to launch their industries, and second, export merchants gained knowledge that was instrumental in fostering the growth of domestic trade.

The “economic take-off,” as described by economist W.W. Rostow, occurred when industrialization progressed slowly over Europe. This period, which was characterized by an increase in GDP, household consumption, savings capacity, and investment, did not occur simultaneously everywhere.

In England between 1780 and 1820, in France between 1830 and 1870, and in Germany between 1850 and 1880, the population “took off,” following a period of rapid population growth due to lower mortality. Sweden and Japan experienced it at the very end of the 19th century, Russia and Canada in the early twentieth century, Latin America and Asia in the 1950s, and several regions of Africa and the Middle East decades later.

The Industrial Revolution in France

In this regard, France was in an unusual situation. From 1815 to 1860, France grew steadily but never had a true “take-off” in the 19th century. Historically, agriculture has played a larger role in the French economy than in other nations, which helps to explain why France is so far ahead of the rest of the pack. Iron output in France was obviously larger than in all of the German states combined by 1860, as the significance of industry in the growth of the industrial revolution increased from 1830 onwards.

The growth of the French railroad network from 3,000 km in 1850 to 17,500 km in 1870 and 50,000 km in 1913 was indicative of the country’s increasing industrialization. The expansion of related sectors like textiles, mining, and steel is further proof; the latter two greatly benefited from the advent of these transportation innovations, as they have been able to bring in new sources of energy, rails, wagons, etc. Thus, the French “performance” is not inconsequential, although it lagged behind England’s throughout the first two-thirds of the century and the United States and Germany’s for the final third.

The Role of the Other Countries in the Industrial Revolution

Both France and Germany faced competition from Britain as they launched industrialization, and the two countries reaped unequal benefits from the latter’s expertise. Free trade agreements between France and Britain were signed in 1860, which coincided with the slowing of the first industrial revolution in France. Due to inadequate industrialization, the French economy suffered as a result of this liberalization of trade (imports tripled, and industrial exports weakened).

Instead, the cards were reshuffled at this time, with Germany benefiting more than England as the latter country lagged behind the fast industrialization that was taking place over the Rhine (creation of large businesses, etc.). The Mediterranean region of Europe, on the other hand, was largely left out of the industrial revolution until the 20th century.

Although the British government had a significant role in fostering industrialization, it played an even larger role in Germany, Japan, Russia, and almost all other 20th-century industrializers. From this point on, the French government also started to meddle more obviously in the economy.

The Consequences of the Industrial Revolution

Heavy industry and emerging industrial sectors, like the car industry, wreaked havoc on the economies of Europe and North America. For the economy to continue operating normally, manufacturers developed modern manufacturing and administrative techniques. Fordism and Taylorism were management philosophies that emerged at the turn of the 20th century. Trusts, cartels, and an increase in the number of stockholders all contributed to a new look for the economy.

Increases in national income per capita, GNP, and GDP are the hallmarks of successful industrialization (GDP). It alters not just how resources are divided but also how people live, work, and interact with one another. Workers’ buying power and living circumstances declined during the outset of the Industrial Revolution in Britain, as they did everywhere, but ultimately improved as a consequence of general enrichment and workers’ fights.

The rise of trade unionism and Marxist socialist ideas at the century’s end led to these developments. However, the Industrial Revolution’s successful social group was the bourgeoisie, which tended to homogenize its way of life across the board, from the upper and lower classes that dominated finance and industry to the middle class that remained the norm despite its diversity.

The Industrial Revolution in a Nutshell

The advent of the new industrial age usually represents a watershed moment in human development. The effects initially appeared in England. The Industrial Revolution catapulted the nation to the position of leading economic power based on new sources of energy (coal), new materials (iron, steel), and advances (textiles, steam engines). However, a worldwide economic slump hit with the Vienna stock exchange crash of 1873.

It wasn’t until 1896 that the second Industrial Revolution, which used electricity, oil, and chemicals, began. The Great Depression of 1929 put an end to the new economy it had helped shape. To all appearances, the 20th century saw a third revolution, one that was mostly driven by technological advancements in areas such as computing, transportation, energy production, and, most notably, communication. But experts believe that it’s too early to judge it at this point.

TIMELINE OF INDUSTRIAL REVOLUTION

1705: Thomas Newcomen builds a steam engine

British engineer Thomas Newcomen, in collaboration with engineer Thomas Savery, developed the first industrially usable steam engine. A few years earlier, Thomas Savery had already invented a steam engine used for pumping water. The collaboration of these two individuals led to the improvement of this device through an atmospheric engine system, or “fire pump.” Newcomen first employed it in 1712 in a mine to operate water pumps. Despite its impracticality and low efficiency, it will be significantly enhanced by engineer James Watt in the coming years.

1709: First use of coke in metallurgy

Abraham Darby, located in the English village of Coalbrookdale, succeeds in melting iron ore using coke. Coke is produced by distilling coal. The long-standing use of coal as an energy source for smelting has led to deforestation in certain European countries. Consequently, new combustion methods needed to be developed. The iron produced by Darby initially lacks quality, but over the following decades, he and his family will refine the process.

1733: John Kay perfects weaving

British inventor John Kay developed the “flying shuttle” to enhance weaving speed. This new mechanical system enables the weaving of threads at a considerable speed and in much wider fabrics, requiring less manual labor. However, the thread production rate becomes insufficient, leading engineers to seek improvements in spinning as well.

1767: The first spinning machine designed by Hargreaves

British weaver James Hargreaves invented the “Spinning jenny,” a spinning frame capable of producing eight threads simultaneously with the effort of a single person. Hargreaves patented it in 1770, leading to an increase in woven threads. However, this system requires human intervention and does not find widespread industrial use.

1769: Richard Arkwright invents the mechanical weaving machine

Richard Arkwright patents his “water frame,” a weaving machine inspired by Hargreaves but powered by a hydraulic engine. This marks the birth of the first mechanical weaving machine, signaling the end of home-based weaving. Factories must now employ personnel to operate the machines. Arkwright himself established a factory in the early 1770s.

1769: James Watt improves the steam engine

James Watt, a Scottish engineer, patented improvements to the steam engine that Newcomen and Savery created. These enhancements include a separate chamber for condensing steam to generate more energy, a double-acting system where steam itself drives the piston, and a flywheel and ball governor to adjust machine speed. Watt continued refining these improvements into the 1780s, collaborating with Matthew Boulton to mass-produce the steam engine. After 1800, further engineers contributed to enhancing the system. The steam engine, powerful and capable of significant energy production, sees increasing use in industry.

1779: Samuel Crompton perfects the weaving machine

Samuel Crompton draws inspiration from Hargreaves and Arkwright to develop his “mule-jenny,” a mechanical weaving machine capable of producing a considerable quantity of threads for all types of fibers. However, this leads to a situation where weavers struggle to keep up with production, resulting in surplus raw materials.

February 13, 1784: Henri Cort invents puddling

British inventor Henri Cort devised the puddling process, refining cast iron—reducing its carbon content—to obtain higher-quality iron or steel. In a high-temperature furnace, cast iron is stirred using a hook and oxidizing slag. This invention represents a significant advancement in metallurgy during the British Industrial Revolution.

1785: Cartwright invents the first mechanical loom

The British inventor Edmund Cartwright developed the first mechanical loom. Since Crompton’s spinning machine, thread production has far outpaced the capabilities of weavers. Cartwright’s system harmonizes raw material production with weaving.

1801: The British Parliament enacts the “General Enclosure Act”

Great Britain established a law definitively instituting enclosure in agriculture. From now on, all agricultural plots will be enclosed and private. Enclosure, implemented since the 13th century, involves fencing off land. This system began developing in the 15th century, leading to large landowners displacing peasants from commons and wastelands, ending communal agricultural exploitation in favor of individualistic production. The expelled, facing ruin, turned to other sectors of production. In the following centuries, the system expanded and, after 1760, spread throughout the country. Enclosure paved the way for commercial agriculture and resulted in the British Agricultural Revolution.

February 21, 1804: First steam locomotive trial

Richard Trevithick set the first steam locomotive in motion in England, and it eventually reached a speed of 8 km/h. Twenty years later, a passenger-carrying line opened. Rapid transportation of significant quantities of goods between different economic zones played a fundamental role in the Industrial Revolution in England.

- Also Read: History of Steam Engines and Steam Power

September 28, 1825: First passenger train transport

The English mechanic and true inventor of the locomotive, George Stephenson, established the first public railway line, connecting Stockton to Darlington. England became the first country to adopt railway lines. In 1829, George Stephenson developed a locomotive that set speed records, named “the Rocket.”

August 27, 1859: Oil gushes in Pennsylvania

American Colonel Edwin Drake constructed the first oil derrick in Titusville, Pennsylvania. Precious liquid emerges when the well reaches a depth of 23 meters. Initially used for oil lamps, petroleum is also distilled for fuel. The oil boom began, leading to the emergence of desert towns and the discovery of new oil fields.

March 6, 1869: Chemistry: Mendeleev presents his periodic table of elements

Russian chemist Dmitri Mendeleev introduced his “periodic classification of elements” to the Russian Chemical Society. His classification of the 63 known chemical elements reveals that the chemical properties of each element repeat at regular intervals. In his table, elements in the same column exhibit comparable properties. Mendeleev’s invention revolutionized the field of chemistry, accommodating newly discovered elements in his periodic table.

May 9, 1873: Vienna stock market crash

The Vienna stock market collapsed, quickly affecting Germany and then the United States. This marks the beginning of a stagnation or economic crisis lasting until 1896. Europe and North America eventually recovered economic growth, notably due to the oil, electricity, and chemical industries. This period is referred to as the “Second Industrial Revolution.”

October 21, 1879: Edison invents the incandescent lamp

Thomas Alva Edison activated the first incandescent light bulb in his New Jersey laboratory in Melo Park. Edison’s invention uses a Japanese bamboo filament in a vacuum-sealed bulb with low voltages to produce electric light when the bamboo carbonizes. The American inventor was only 29 years old at the time. The public was amazed when his invention was presented on January 1, 1880.

January 29, 1886: Carl Benz patents the first automobile

Installing an internal combustion engine on a tricycle equipped with a gearbox and differential, Carl Benz (or Karl Benz) built what is considered the first automobile. While motorized vehicles had been constructed before, such as Joseph Cugnot’s steam farrier, Benz’s tricycle was the first complete automobile capable of commercialization and industrial production. Soon, the automobile industry will flourish, giving rise to numerous brands and models. Carl Benz will become the head of a thriving company that, through mergers, continues today under the name DaimlerChrysler.

1911: Taylor publishes “The Principles of Scientific Management”

Frederick Winslow Taylor, a German-born engineer, published a work outlining his organizational system of work. Later called “Taylorism,” it relied on the scientific organization of labor, aiming to improve the speed of employees’ execution and production. After years of analysis at his company, the Midvale Steel Corporation, he initially advocated for the separation of tasks. Managers design and schedule, while workers limit themselves to execution in assigned positions. This new method yields positive results but is not appreciated by workers, who feel transformed into mere machines.

January 14, 1914: Birth of “Fordism”

American automobile manufacturer Henry Ford introduced an innovative method of assembly line work: the assembly line. With this innovation, the Ford Model T‘s construction time dropped from 6 hours to 1.5 hours, and factory productivity increased by a factor of 4. The static worker now assembles parts passing in front of them. This marks the birth of Fordism.

October 24, 1929: Black Thursday on Wall Street

On this day, the New York Stock Exchange collapsed. In just a few hours, 12 million shares were sold on the market. Seeing the decline in prices, speculators try to quickly get rid of all their stocks. Prices plummet by 30%. The “crash” will be confirmed on Tuesday, October 29. “Black Thursday” initiated the most severe economic crisis in history, the “Great Depression” of 1929. The United States is left in ruins, and the world is impacted both politically and economically.