Samsung’s Galaxy Ring, anticipated as a major innovation in connected devices, is facing difficulties that are beginning to harm its reputation. Praised for its design and advanced health-tracking capabilities, the ring’s battery life is dropping alarmingly after just a few weeks of use. Users who were counting on this feature find themselves having to recharge their ring after only three days.

In addition to this problem, other surprising revelations have now emerged following its disassembly by iFixit.

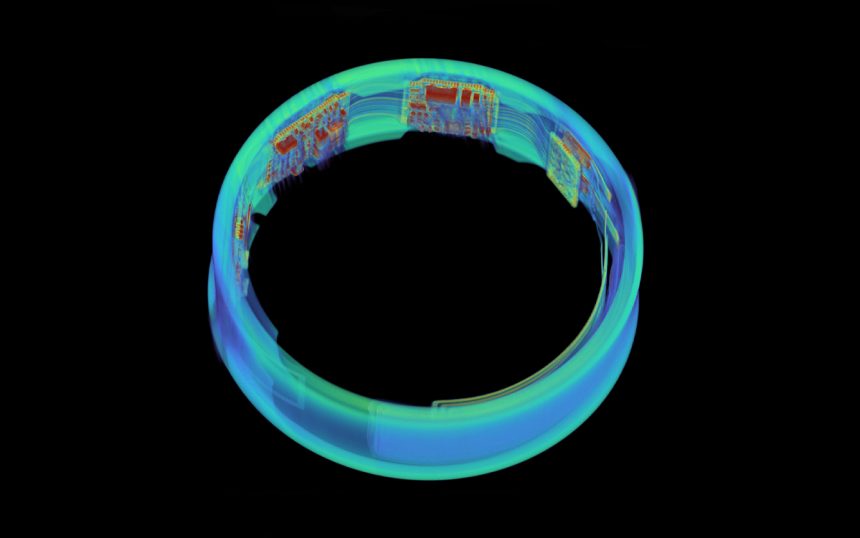

The Galaxy Ring, despite its simple appearance, conceals complex technology. The iFixit team, which specialized in dismantling electronic devices, discovered that Samsung made design choices primarily motivated by economic imperatives.

In addition to its recent battery life issues, the inside of the ring reveals a manufacturing method that is surprising for a product of this scale.

The Galaxy Ring Hides Economical Design Choices

The disassembly of the Galaxy Ring revealed that Samsung opted for a pressure connector to link the battery and the inductive charging coil to the motherboard. This choice, although convenient for assembly, seems contradictory since the ring is designed to be non-repairable. The use of this type of connector rather than soldering is explained by the desire to reduce costs and accelerate production. However, this industrial compromise could disappoint those who expected better durability.

This approach sharply contrasts with that adopted by other manufacturers, such as Oura, who prioritize a more traditional and durable design with soldered components. The Oura Ring 3, for example, has its motherboard directly soldered to the charging coil. Apart from this cost-saving measure, the other internal components of the Galaxy Ring don’t really bring any surprises.

It uses technologies that are already widely spread. With the persisting battery life problems, these design choices reinforce users’ concerns about the long-term reliability of this otherwise innovative device.

Source: iFixit