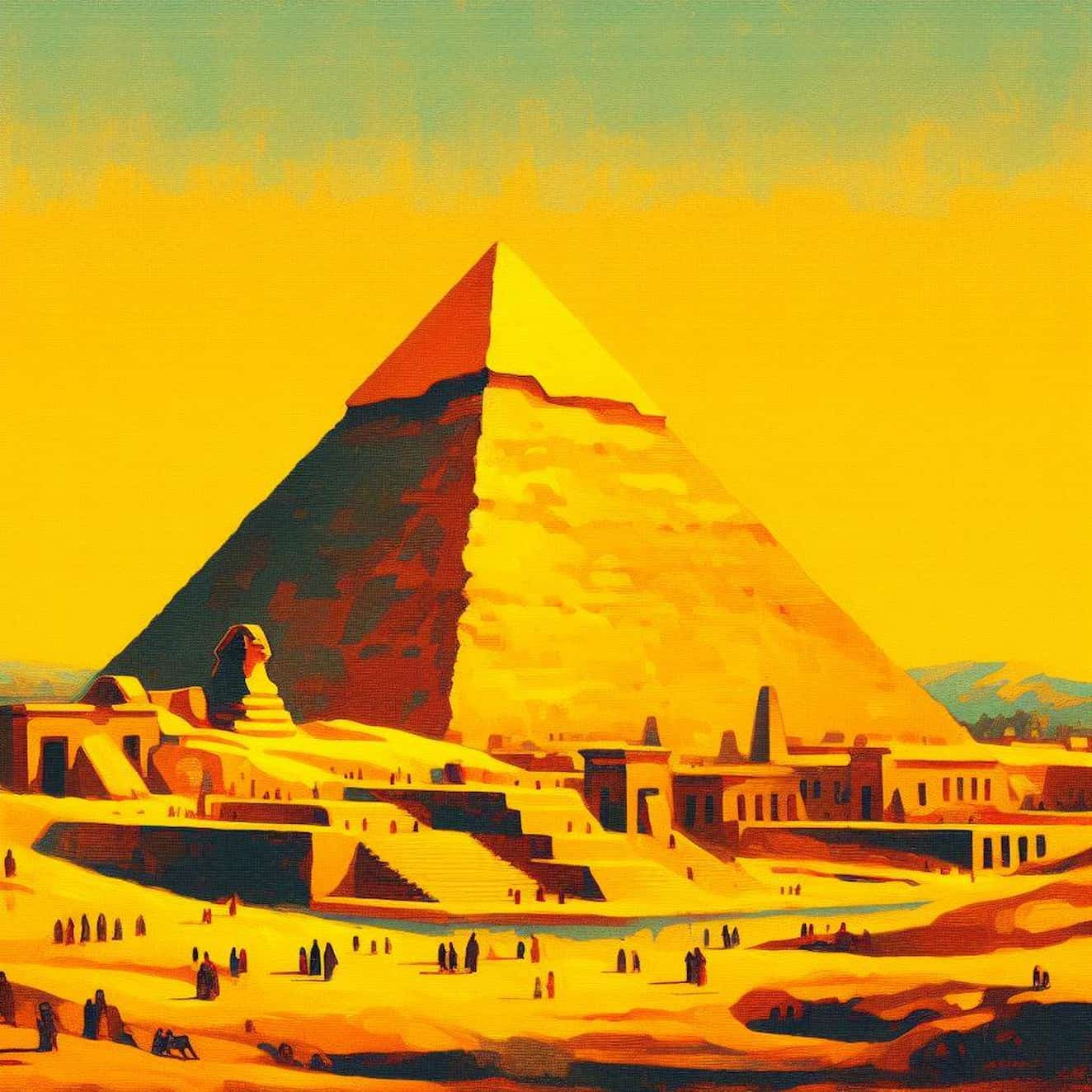

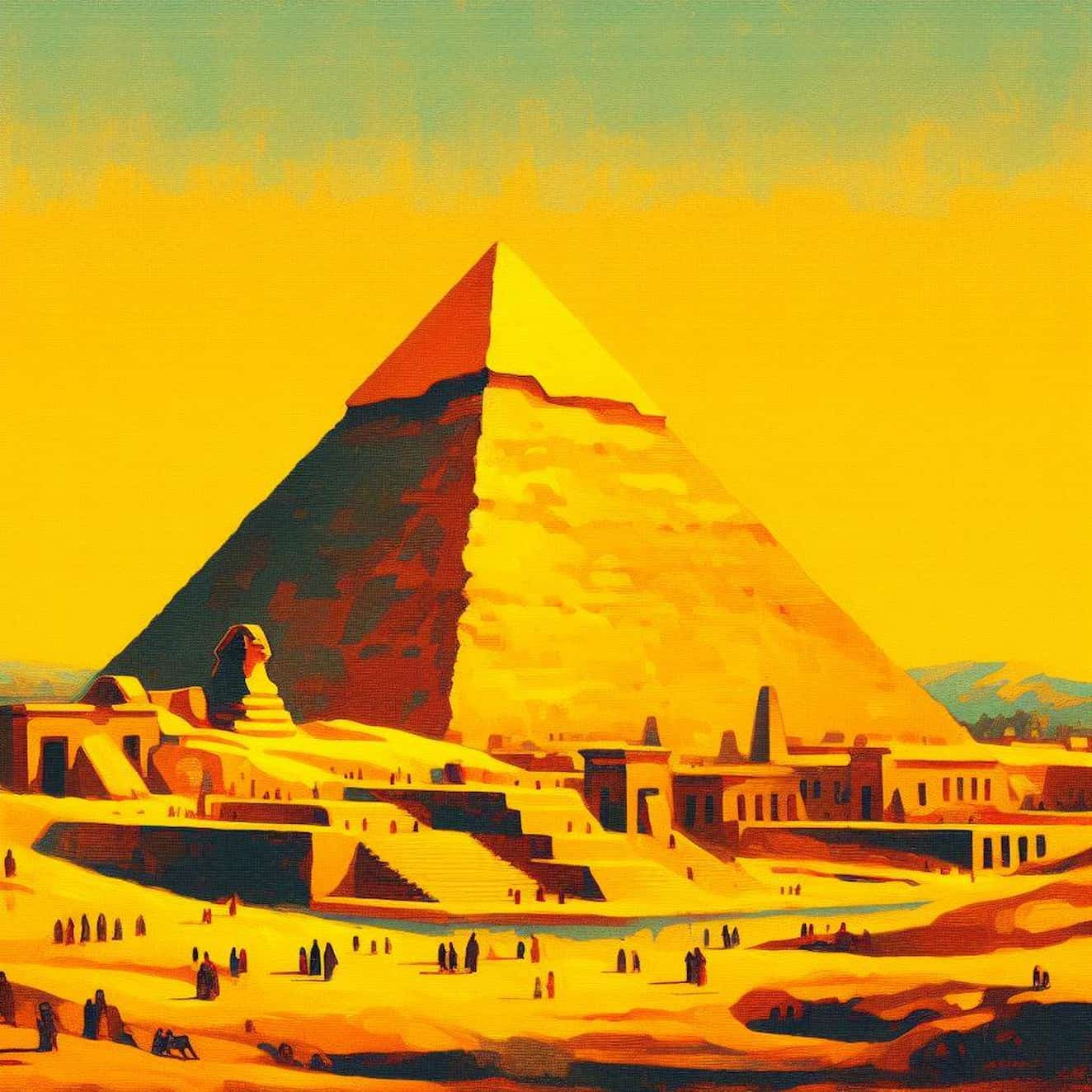

Egyptian Pyramid Construction Techniques

The ancient Egyptians had to solve the numerous problems posed by the construction of the pyramids with the resources and technical knowledge available to them at the time.

The ancient Egyptians had to solve the numerous problems posed by the construction of the pyramids with the resources and technical knowledge available to them at the time.